In the demanding worlds of mining and aggregate processing, operational success hinges on the reliability of your screening media. While much attention is given to material grade and panel design, the true hero often remains behind the scenes: the precision molding process. This critical manufacturing step is what transforms raw polyurethane into high-performance, durable screen panels.

The journey to a flawless screen begins with a meticulously crafted mold. High-precision molds dictate every critical aspect of the final product—from aperture shape and size to the panel's overall thickness and structural integrity.

Perfect Fit: Panels produced with tight tolerances ensure seamless integration onto the screening deck.

Stable Operation: This perfect fit promotes uniform tension across the entire deck, drastically reducing harmful vibrations and uneven wear.

Extended Lifespan: Consistent dimensions lead to predictable performance, prolonging the service life of both individual panels and the complete deck system.

The mold's surface quality is directly imprinted onto the polyurethane screen. A superior, precision-finished mold results in a remarkably smooth panel surface.

Reduced Blockages: This smoothness minimizes material adhesion, effectively combating pegging and blinding—common issues with wet or sticky ores.

Boosted Efficiency: Uninterrupted material flow translates directly into higher throughput and more accurate particle separation, saving both time and energy.

A screen's strength is tested by constant impact and vibration. Precision molding is key to building robust internal bonds.

Optimized Parameters: Carefully controlled temperature, injection speed, and curing pressure ensure the polyurethane fully bonds to the embedded steel frame.

Prevents Failure: This robust integration eliminates delamination, the separation of polyurethane from the frame, which is a primary cause of premature screen failure in high-abrasion and dewatering tasks.

Investing in precision molding is an investment in sustainability and cost-effectiveness.

Minimized Waste: Accurate molds produce panels that are right the first time, drastically cutting down on manufacturing scrap, rework, and installation errors.

Lower Operational Costs: Perfectly matched panels install faster, reduce system downtime, and eliminate leakage points caused by misfit edges, leading to a significantly lower total cost of ownership.

As the global demand for more efficient and longer-lasting screening solutions grows, the industry is embracing smart manufacturing.

At HUATAO Group, we are at the forefront of this evolution with our advanced production capabilities:

CNC-Controlled Mold Systems for micrometer-level accuracy in every panel.

Automated Mixing & Curing for unbeatable polymer consistency and quality.

Digital Inspection Tech for real-time quality control and dimensional verification.

This commitment to innovation ensures that every HUATAO screen delivers peak performance, remarkable durability, and unwavering accuracy throughout its entire lifecycle.

Precision molding is not just a step in production; it is the very foundation of screen excellence. It guarantees the consistency, strength, and efficiency that modern mining and aggregate operations require. By mastering this process, manufacturers can provide screens that withstand extreme conditions, optimize output, and drive down costs.

HUATAO Group is dedicated to empowering our customers with these exact benefits—delivering longer uptime, reduced maintenance, and superior screening results through every perfectly molded panel we produce.

About HUATAO Group

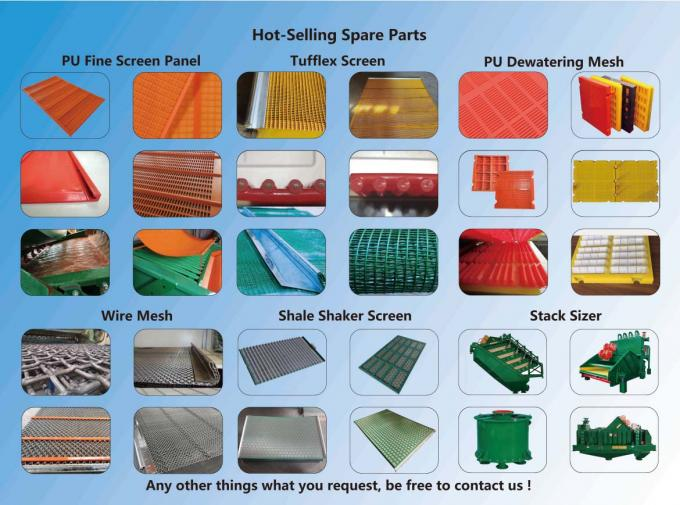

HUATAO Group is a leading global provider of high-performance polyurethane screen panels, rubber screens, and wear-resistant solutions for the mining, quarrying, and industrial sectors. We combine reliable products with deep technical expertise and responsive on-site support to maximize your operational efficiency and minimize downtime.

Contact: annie.lu@huataogroup.com

Website: www.tufflexscreen.com

WhatsApp: +86 18032422676

#PrecisionMolding #PolyurethaneScreen #MiningEfficiency #ScreeningSolutions #MiningIndustry #AggregateProcessing #ManufacturingExcellence #Innovation #Engineering #QualityControl #Durability #CostReduction #Sustainability #DigitalManufacturing #HUATAOGroup #IndustrialScreening #WearResistant #Pegging #Blinding #DowntimeReduction

can not be empty

can not be empty