Wet screening operations in mineral processing and aggregate production face persistent efficiency challenges that directly impact profitability and sustainability. Traditional screening media often prove inadequate against issues like material adhesion, particle lodging, and rapid wear.

Advanced polyurethane screening systems offer comprehensive solutions to these operational hurdles, delivering enhanced performance and reduced total cost of ownership.

The accumulation of sticky materials on screening surfaces represents a significant efficiency barrier in wet processing applications. Polyurethane's inherently low-adhesion properties create a self-cleaning surface that minimizes material buildup, maintaining consistent screening performance without frequent operational interruptions.

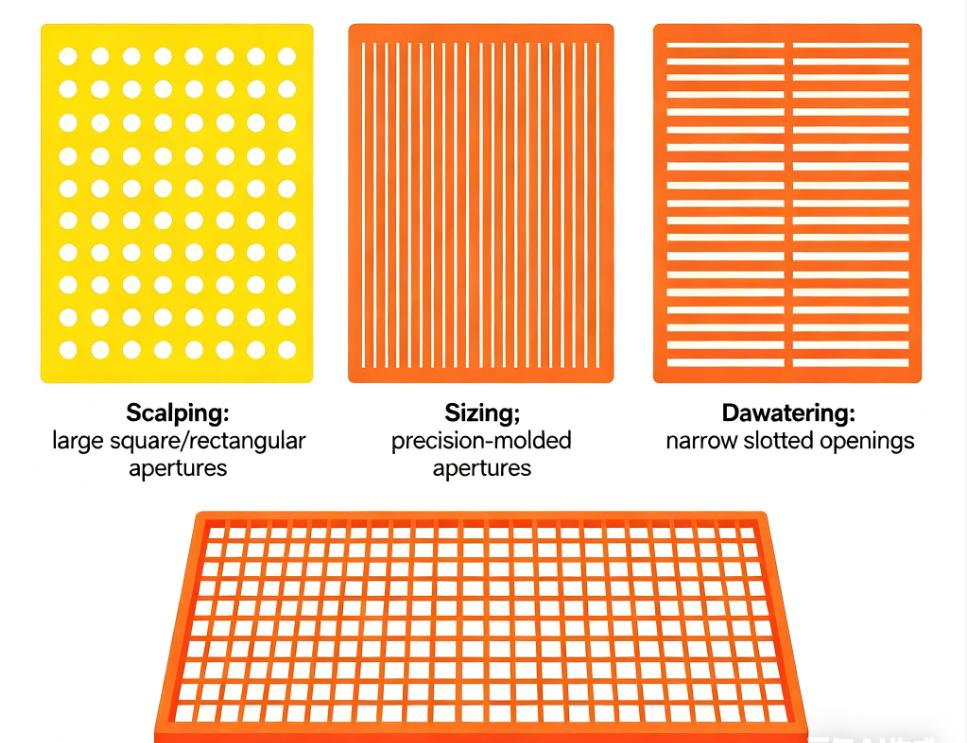

Near-size particles frequently become lodged in screen apertures, compromising classification accuracy. Polyurethane's flexible nature creates dynamic aperture movement that gently ejects trapped particles through what's known as the "hourglass effect," ensuring consistent product sizing throughout production cycles.

The abrasive nature of mineral slurries rapidly degrades conventional screening media. Polyurethane's exceptional wear resistance provides service life 3-5 times longer than traditional materials, significantly reducing replacement frequency and associated maintenance costs.

Metal screening surfaces generate substantial operational noise that can exceed safety thresholds. Polyurethane's natural sound-dampening characteristics create quieter working environments while supporting compliance with occupational health regulations.

Inefficient screening often necessitates excessive water usage to maintain material flow. Polyurethane's non-stick properties enable effective separation with reduced water volumes, supporting more sustainable water management practices and decreasing downstream processing requirements.

| Operational Challenge | Traditional Screens | Polyurethane Screens |

|---|---|---|

| Blinding & Adhesion | Frequent cleaning required | Excellent resistance, self-cleaning |

| Pegging | Common, manual intervention needed | Minimal due to dynamic flexing |

| Abrasive Wear | 3-6 month typical lifespan | 12-24+ month service life |

| Operational Noise | Often exceeds safety limits | Significantly reduced |

| Water Consumption | High volumes typically required | Reduced requirements |

Polyurethane screening technology represents a strategic advancement for wet processing applications, directly addressing the most persistent operational challenges through superior material properties. The resulting improvements in efficiency, cost management, and environmental performance deliver compelling value for modern mineral processing operations.

HUATAO Group provides comprehensive polyurethane screening solutions backed by technical expertise and support services.

Contact Information:

Email: annie.lu@huataogroup.com

Website: www.tufflexscreen.com

WhatsApp: +86 18032422676

#PolyurethaneScreen #WetScreening #MineralProcessing #ScreeningEfficiency #MiningSolutions #AbrasionResistance #ScreeningTechnology #HUATAOGroup #IndustrialScreening #MiningEquipment

can not be empty

can not be empty