The transformation of bauxite ore into high-purity alumina represents a complex industrial process where screening efficiency directly impacts operational economics and product quality. HUATAO GROUP's engineered polyurethane screening solutions address the unique challenges of bauxite processing, delivering enhanced performance and reduced total cost of ownership.

Efficient screening constitutes a fundamental quality control point in alumina production, influencing multiple aspects of the Bayer process:

Optimal particle size distribution for digestion efficiency

Minimized recirculating loads in grinding circuits

Reduced energy consumption throughout the production chain

Prevention of downstream contamination

Traditional screening media often prove inadequate against bauxite's abrasive, moist, and chemically challenging characteristics.

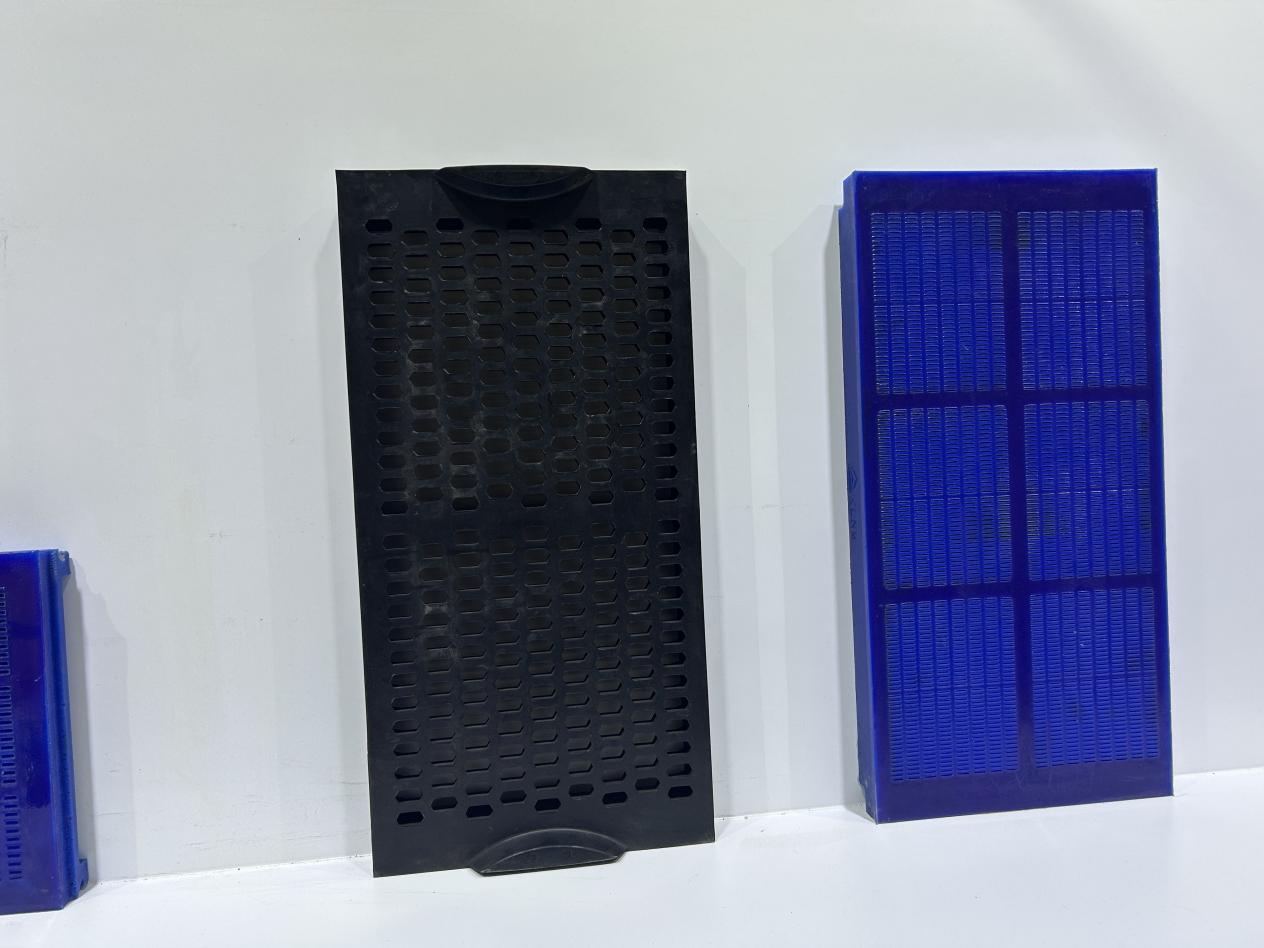

Enhanced Durability in Abrasive Environments

Specialized polyurethane compounds demonstrate exceptional wear resistance, providing service life 5-8 times longer than conventional steel screens. This extended lifespan significantly reduces replacement frequency and associated maintenance costs.

Superior Anti-Blinding Performance

The flexible, non-stick surface properties of polyurethane prevent the accumulation of clay and moist particles that typically cause screen blinding. This maintains consistent screening efficiency and maximizes throughput.

Chemical Resistance in Caustic Environments

Polyurethane screening media withstand the corrosive conditions present in Bayer process digestion stages, ensuring long-term structural integrity and consistent performance.

Precision Sizing Capabilities

Accurately molded apertures maintain dimensional stability throughout the screen's service life, ensuring consistent particle size control critical for digestion efficiency.

Implementation of polyurethane screening technology delivers measurable improvements across key performance indicators:

Increased production availability through reduced downtime

Lower operating costs via extended service life

Enhanced screening efficiency and product consistency

Improved workplace safety through noise reduction

HUATAO GROUP provides tailored screening solutions designed to address specific bauxite characteristics and processing requirements. Our technical expertise supports optimal screen configuration selection based on comprehensive material analysis and operational objectives.

Advanced polyurethane screening technology represents a strategic investment for bauxite processing operations seeking to optimize efficiency, reduce costs, and maximize alumina recovery. The demonstrated performance advantages establish polyurethane as the preferred screening media for modern alumina production facilities.

Contact Information:

Email: annie.lu@huataogroup.com

Website: www.tufflexscreen.com

WhatsApp: +86 18032422676

#PolyurethaneScreens #BauxiteProcessing #AluminaProduction #MiningSolutions #HUATAOGROUP #ScreeningTechnology #MineralProcessing #MiningEfficiency #IndustrialScreening #AluminumIndustry

can not be empty

can not be empty