Industrial screening operations demand reliability and efficiency to maintain productivity and reduce operational costs. Traditional steel screens often fall short when handling wet, sticky, or abrasive materials, leading to frequent clogging and premature wear. Rubber screen mesh, engineered with elastic polymer materials and precision design, addresses these challenges effectively.

Anti-Blinding Performance

The elastic surface of rubber screen mesh generates micro-vibrations during operation, preventing fine particles from adhering to the screen. This feature ensures stable screening efficiency, even for materials with moisture content exceeding 30%.

Exceptional Wear Resistance

Rubber screen mesh offers a service life 3-5 times longer than traditional steel screens. Its resistance to impact and corrosion makes it ideal for harsh industrial environments.

Energy Efficiency and Durability

With a weight reduction of 50% compared to steel screens, rubber screen mesh lowers equipment power consumption by 15-20%. Its flexible structure also absorbs shocks, protecting supporting machinery and reducing failure rates.

Mining Industry

Suitable for screening high-hardness ores such as iron ore, copper ore, and bauxite, rubber screen mesh ensures precise classification without deformation.

Coal Processing

Ideal for coal washing and dewatering, it efficiently separates coal slime from water, reducing filter cake moisture content to below 15%.

Aggregate Production

Adaptable to wet sand and gravel classification, rubber screen mesh delivers high screening accuracy and supports continuous production lines.

Environmental Protection

Used in sludge dewatering for wastewater treatment, it resists chemical corrosion and minimizes maintenance frequency.

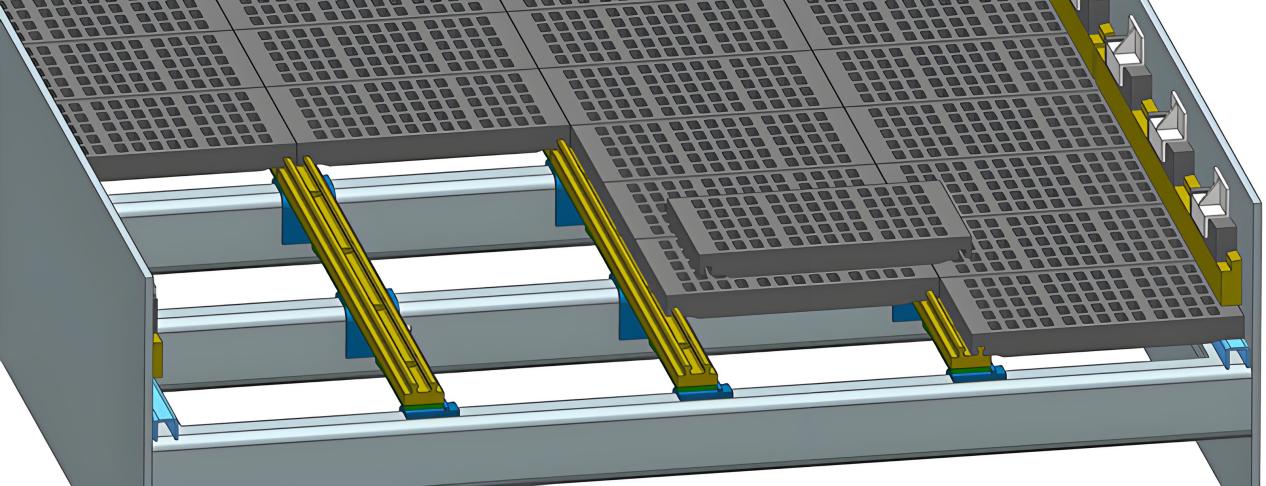

Choosing the right rubber screen mesh requires understanding material properties such as particle size, moisture content, and abrasiveness. HUATAO Group offers customized solutions tailored to specific operational needs, including aperture size, thickness, and installation structure. Our technical team provides free material analysis and on-site guidance to ensure seamless integration with existing equipment.

Rubber screen mesh represents a significant advancement in screening technology, combining anti-clogging capabilities, durability, and energy efficiency. By adopting this solution, industries can achieve higher productivity, reduced downtime, and lower operational costs.

For tailored screening solutions, contact HUATAO Group today.

Contact Information:

Email: annie.lu@huataogroup.com

Website: www.tufflexscreen.com

WhatsApp: +86 18032422676

#RubberScreenMesh #IndustrialScreening #AntiClogging #WearResistant #HUATAOGroup #MiningSolutions #Efficiency #CostReduction

can not be empty

can not be empty