Vibrators serve as the fundamental power source for vibrating screens, generating precise excitation forces that drive material movement for efficient screening, grading, and conveying. Understanding their operation and maintenance is crucial for maximizing performance and equipment longevity.

Understanding Vibrators: The Driving Force

Functioning as the essential component of vibrating screens, vibrators produce controlled vibrations that propel the screen box. This mechanical motion ensures consistent material flow and effective separation - vital for operations across mining, aggregates, and recycling industries.

Primary Types of Vibrators

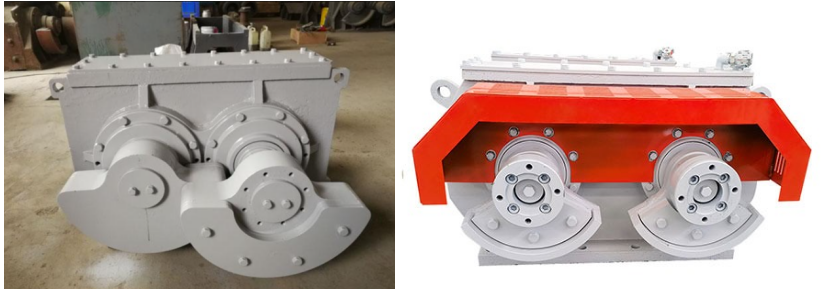

Inertial Vibrators

Single-Axis: Utilizes eccentric wheels or shafts to create circular vibration patterns, ideal for circular motion screens

Dual-Axis: Combines two vibrators to generate linear vibration, suitable for linear screens and heavy-duty applications

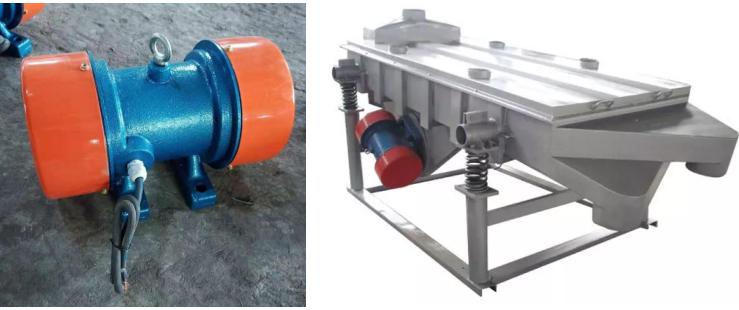

Vibration Motors

Integrates motor and vibrator into a single compact unit

Advantages: Simple design with easy excitation adjustment through eccentric mass modification

Limitations: Best suited for small to medium-sized screens due to restricted force capacity

Electromagnetic Vibrators

Employs magnetic force to vibrate specifically the screen surface rather than the entire structure

Particularly effective for dewatering applications and fine-particle screening

Reduces structural vibration transmission and energy consumption

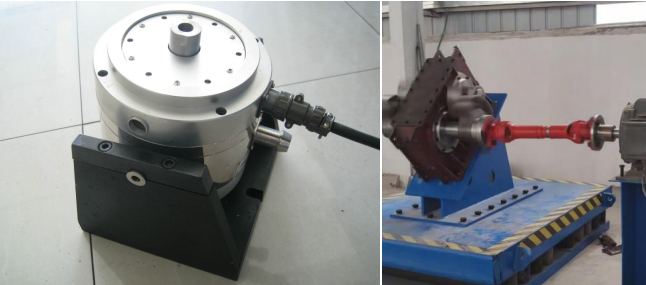

Excitation Force Adjustment and Maintenance Protocols

Performance Optimization

Modify eccentric mass, radius, or operational speed to align with material characteristics and screening objectives

Vibration motors enable precise force control through adjustable eccentric angles

Systematic Maintenance

Conduct regular component inspections for wear identification

Perform routine cleaning of internal dust and debris accumulation

Verify fastener integrity and maintain proper lubrication systems

Ensure correct alignment and operation of motors and drive components

Proper maintenance protocols significantly extend vibrator service life and guarantee screening process stability.

Conclusion

Strategic vibrator selection and systematic maintenance directly influence screening efficiency, energy consumption, and operational expenditures. Each vibrator type - whether inertial, motor-driven, or electromagnetic - offers distinct advantages tailored to specific operational requirements.

Enhancing your understanding of vibrator technology directly correlates with improved screening performance.

Professional Support Available

Annie Lu | Huatao Group

Email: annie.lu@huataogroup.com

Phone: +86 18032422676 (WhatsApp/WeChat)

Website: www.tufflexscreen.com

Industry Hashtags

#Vibrator #VibratingScreen #Exciter #ScreeningEquipment #MaintenanceGuide #MiningEquipment #AggregateIndustry #MaterialHandling #VibrationMotor #InertialVibrator #ElectromagneticVibrator #IndustrialMaintenance #EquipmentEfficiency #ScreeningTechnology #Engineering #MechanicalVibration #OperationalExcellence #QuarryLife #MineralProcessing #IndustrialAutomation

can not be empty

can not be empty