Vibrating screens are vital equipment in industrial operations like mining, construction, and chemical processing—but two common issues often hinder their performance: mesh blinding (clogging) and rusting. Both problems drastically reduce screening efficiency, shorten equipment lifespan, and increase operational costs. This guide dives into the root causes of these issues, offers actionable preventive measures, and shares practical solutions to keep vibrating screens running smoothly. Whether you’re processing coal, aggregates, or chemical materials, these strategies will help enhance your screen’s performance and durability.

Part 1: Analyzing Vibrating Screen Mesh Blinding & Solutions

During daily operation, vibrating screen meshes often get clogged due to the diverse properties and shapes of processed materials. Understanding the key causes of blinding is the first step to solving it:

Key Causes of Mesh Blinding

- High Concentration of Near-Separation-Size Particles: Materials with a large number of particles close to the screen’s separation size easily get stuck in the mesh openings, creating blockages that slow down material flow.

- Excess Moisture in Materials: When materials have high moisture content, fine particles stick to the mesh surface. Over time, this adhesion builds up, covering the mesh and reducing effective screening area.

- Spherical or Multi-Contact-Point Particles: Spherical particles or materials that make multiple contact points with the mesh tend to accumulate in the openings, rather than passing through or being retained efficiently.

- Static Electricity Generation: Some materials generate static electricity during screening. This static charge attracts fine particles, causing them to clump together and clog the mesh.

- Fibrous Material Content: Materials with fibrous components (e.g., certain ores or recycled materials) easily entangle with the mesh wires, forming tangles that block openings.

- Abundant Flaky Particles: Flaky particles are more likely to wedge into mesh openings—their flat shape prevents them from falling through or being shaken loose, leading to persistent clogging.

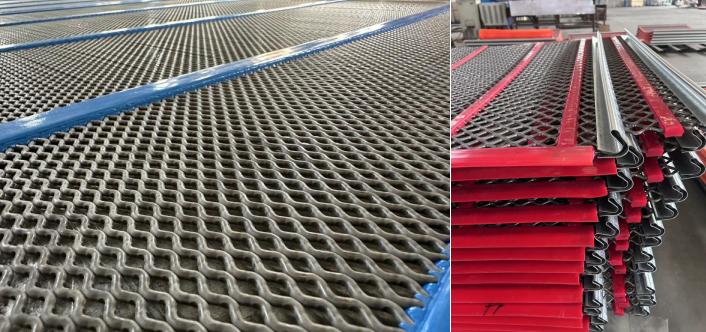

- Overly Thick Woven Screen Wires: Woven screens with excessively thick wires reduce the effective open area of the mesh. This limited space increases the chance of particles getting stuck, as there’s less room for material to pass through.

- Poor Mesh Design in Thick Screens: Thick screens (such as rubber screens) that lack a “wide-top, narrow-bottom” aperture design trap particles. Without this tapered shape, particles can’t slide through easily and remain stuck in the openings.