Innovation in Screening: Polyurethane Panels Set New Performance Benchmarks for the Mining Industry

The core screening process in mining and aggregate production has long relied on heavy-duty steel panels. However, evolving operational demands for higher efficiency, lower downtime, and improved cost management are driving a significant material shift. Polyurethane (PU) screen panels are now at the forefront of this transformation, offering a compelling array of technical and economic benefits.

Addressing the Limitations of Traditional Screening Media

Conventional steel screen panels, while initially cost-effective, grapple with inherent challenges. Their substantial weight complicates handling and installation, leading to longer maintenance windows. More critically, they are prone to accelerated wear from abrasive ores and are susceptible to blinding when processing moist, sticky materials—a common scenario in many mines—which throttles throughput and increases operational costs.

The Engineering Superiority of Polyurethane Composites

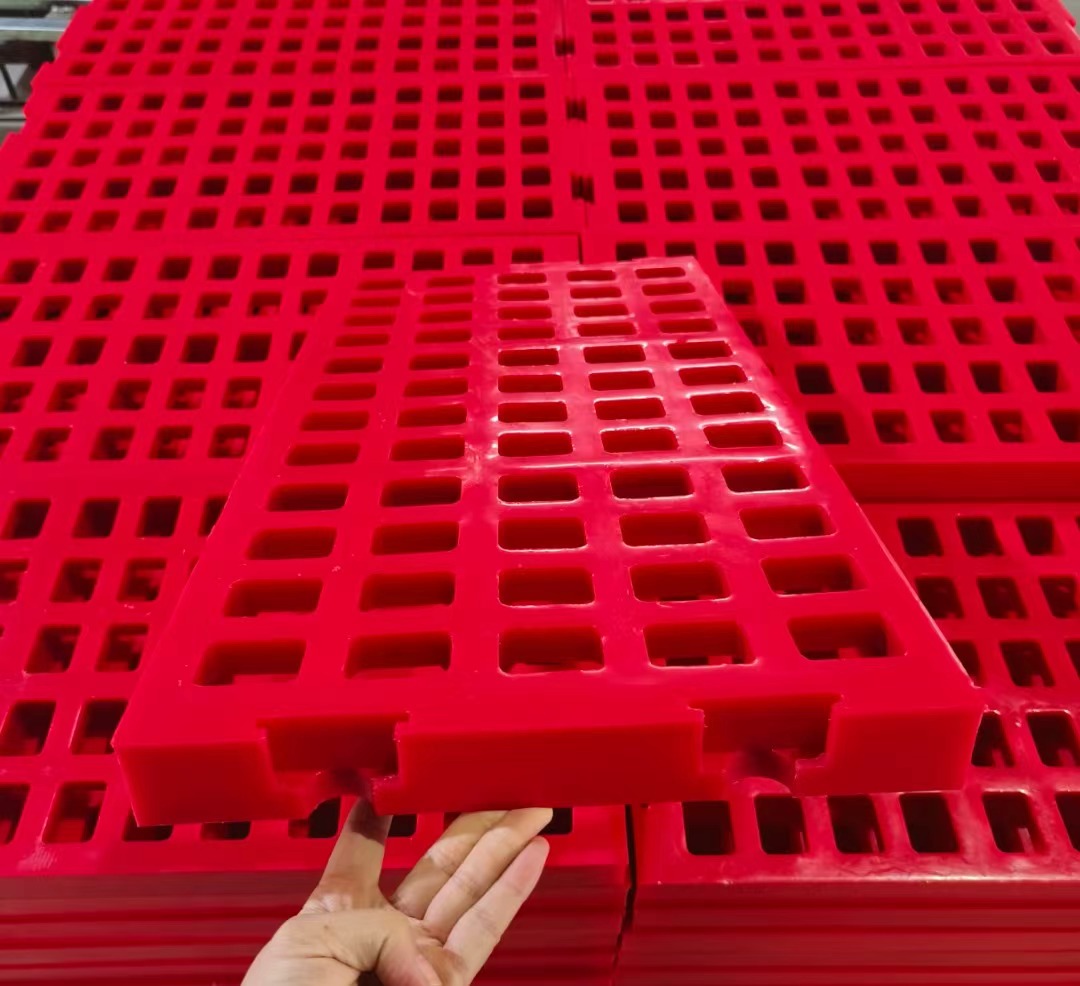

Modern polyurethane screen panels are not simple polymers; they are sophisticated composites. By integrating reinforcing meshes or fibers, manufacturers create a product that marries the elasticity of urethane with structural integrity. This results in a screening surface uniquely suited to withstand the punishing environment of a vibrating screen deck.

A Comparative Analysis of Key Performance Metrics

Durability and Lifespan: The exceptional abrasion resistance of high-grade polyurethane allows these panels to absorb the kinetic energy of falling rock, reducing wear. Industry data consistently shows service life improvements of 300% to 500% over standard steel screens.

Operational Efficiency: The non-adhesive surface and potential for tapered aperture design prevent material buildup, ensuring consistent open area and screening accuracy. This is particularly valuable in dewatering applications or regions with high rainfall.

Safety and Ergonomics: Weighing roughly half as much as equivalent steel panels, PU screens mitigate manual handling risks and streamline the replacement process. Furthermore, their noise-dampening properties contribute to a safer, more compliant workplace.

Economic Justification and Return on Investment

A holistic cost analysis reveals the true value of polyurethane technology. Although the purchase price per unit is higher, the extended service interval, reduction in downtime for changes, and sustained screening performance lead to a significantly lower cost-per-ton processed. This positions PU panels not as an expense, but as a strategic investment in operational efficiency and predictability.

Conclusion: A Smart Investment for Modern Operations

The transition to polyurethane screen panels is a clear indicator of an operation prioritizing long-term productivity and cost management. By delivering unmatched wear life, reliability in difficult conditions, and measurable operational savings, they represent the new standard in screening media for forward-thinking mining and aggregate producers.

For detailed case studies, product specifications, or application consulting, please contact our specialists.

Annie Lu

Huatao Group

Email: annie.lu@huataogroup.com

Mobile: 0086 18032422676 (WhatsApp/WeChat/Viber)

Website: http://www.tufflexscreen.com

#PolyurethaneScreens #MiningInnovation #ScreeningTechnology #AggregateIndustry #WearResistantMaterials #OperationalEfficiency #DowntimeReduction #CostPerTon #MiningSolutions #MineralProcessing #VibratingScreenDeck #AntiBlindingTechnology #MaterialHandlingSafety #NoiseReduction #IndustrialPolymers #ScreeningMedia #MiningProductivity #QuarryManagement #HeavyDutyApplications #ProcessOptimization

can not be empty

can not be empty