Advanced Polyurethane Screens: Precision Engineering for Modern Iron Ore Beneficiation

In iron ore processing, screening efficiency is not merely an operational metric—it is a critical determinant of product quality, throughput, and profitability. As ore grades decline and processing environments become more challenging, the limitations of traditional steel and rubber screening media become increasingly apparent. HUATAO GROUP addresses these challenges through engineered polyurethane screen solutions designed for precision, durability, and optimal total cost of ownership.

The Screening Challenge in Iron Ore Processing

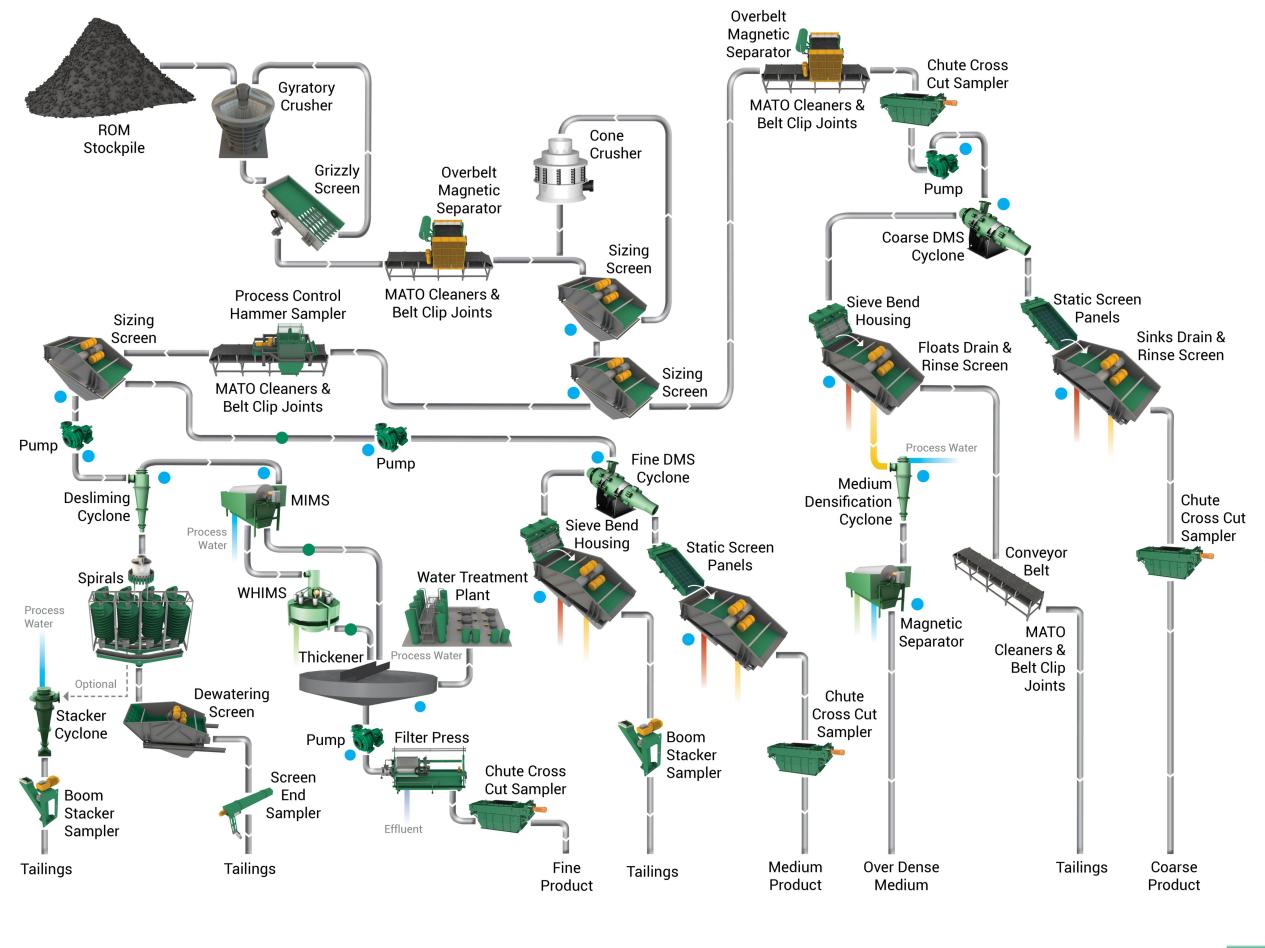

The journey from run-of-mine ore to high-grade concentrate involves multiple screening stages, each with distinct demands:

Primary Screening: Requires extreme impact resistance to handle large, abrasive rocks.

Wet Screening: Demands media that resist blinding from clay and fine silica in water-saturated conditions.

Precision Grade Control: Necessitates exact aperture consistency to meet stringent product specifications, where minor deviations can significantly impact value.

Superior Performance of Engineered Polyurethane

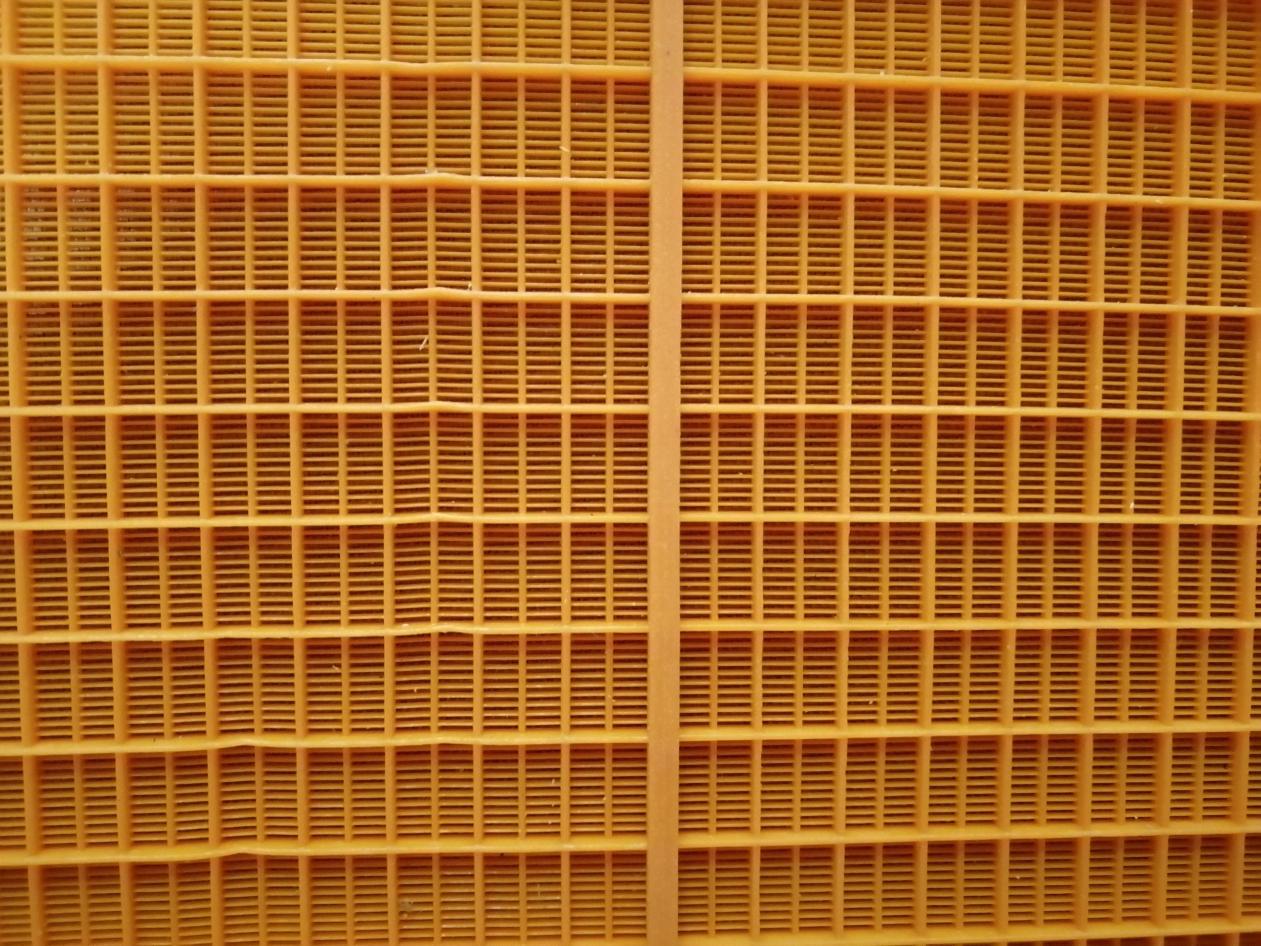

Polyurethane screens offer a compelling advantage due to their unique material properties:

Exceptional Abrasion Resistance: Advanced polymer formulations provide a service life 3 to 8 times longer than standard steel screens in high-wear applications.

Anti-Blinding Characteristics: The non-adhesive surface and flexible aperture design prevent material buildup, ensuring consistent throughput and screening accuracy in wet processing.

Precision and Consistency: Manufacturing techniques allow for aperture tolerances as tight as ±0.05mm, essential for final concentrate grading and premium product pricing.

HUATAO GROUP’s Dedicated Screening Solutions

Our product development is focused on application-specific performance:

HT-MIN70 Series: Engineered for fine screening (<1mm) with a micro-elastic surface that prevents near-size particle adhesion.

HT-HEAVY Series: Designed for high-impact primary and secondary screening, featuring reinforced backing for maximum stability.

Custom Engineering: We provide tailored solutions including specific aperture profiles, tensioning systems, and mounting configurations to integrate seamlessly into existing circuits.

Conclusion: A Strategic Investment in Efficiency

Transitioning to high-performance polyurethane screens represents a strategic operational upgrade. The combination of extended service life, reduced downtime for changes, and improved screening accuracy delivers a demonstrable reduction in cost per ton processed and a strong return on investment.

For detailed technical specifications or to discuss a screening audit for your operation, please contact our team.

Annie Lu | Huatao Group

Email: annie.lu@huataogroup.com

Mobile: +86 18032422676 (WhatsApp/WeChat)

Website: www.tufflexscreen.com

#IronOreScreening #PolyurethaneScreens #MineralProcessing #Beneficiation #ScreeningTechnology #MiningEquipment #OreGrading #HUATAOGROUP #WetScreening #AbrasionResistant #PrecisionScreening #CostOfOwnership #MiningSolutions #ProcessingEfficiency

can not be empty

can not be empty