In today’s competitive mining and aggregate sectors, operational efficiency and cost management are paramount. Screening represents a critical stage where performance directly influences throughput, product quality, and profitability. Traditional screening media, such as steel mesh and rubber panels, often fall short in demanding applications due to rapid wear, blinding, and maintenance intensity.

Polyurethane screens have emerged as a technologically advanced solution, engineered to address these limitations. This article examines the key properties and benefits that establish polyurethane as the preferred screening medium for modern mineral processing operations.

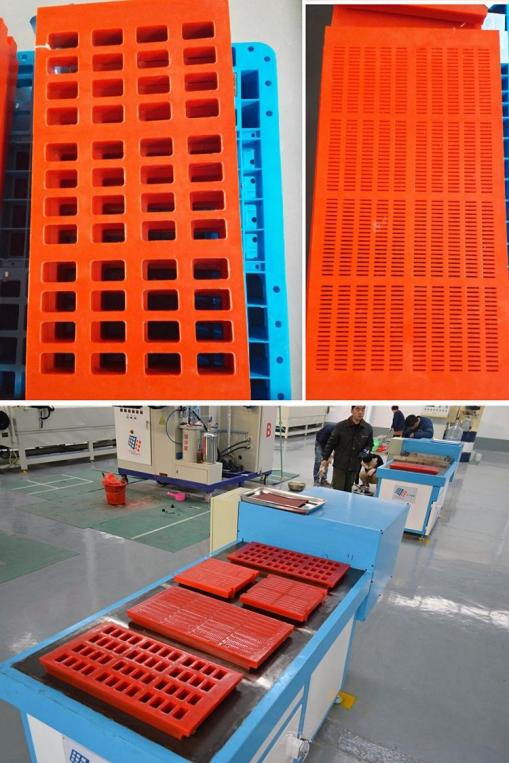

The abrasive nature of ores and aggregates poses a significant challenge to screening equipment. Polyurethane screens are formulated to exhibit exceptional resistance to abrasion, impact, and fatigue failure. Their elastomeric composition allows them to absorb energy from falling material, reducing surface degradation and extending service life substantially—often two to five times longer than conventional steel or rubber screens. This durability translates directly into reduced replacement frequency, lower spare parts inventory, and decreased maintenance-related downtime.

Consistent aperture size is vital for precise particle separation. Polyurethane screens are manufactured using controlled molding processes, ensuring dimensional accuracy and uniformity of each opening. Furthermore, the material’s inherent flexibility aids in reducing blinding and pegging. The screens often feature tapered aperture designs that promote particle passage and a natural self-cleaning action during vibration, leading to higher screening efficiency and more reliable product gradation in both wet and dry applications.

Plant safety and compliance with occupational health standards are increasingly important. Steel screens can generate high levels of noise due to material impact and metal-to-metal contact. Polyurethane’s noise-dampening properties significantly lower operational decibel levels, contributing to a safer and more comfortable working environment. Additionally, their lighter weight and reduced vibration transmission decrease mechanical stress on screening machines, enhancing overall system stability and longevity.

Processing environments often involve moisture, slurry, or exposure to chemicals. Unlike steel, which is prone to corrosion, or rubber, which may degrade or swell, polyurethane maintains its structural integrity and performance characteristics under such conditions. Its resistance to water, oils, and a range of acidic or alkaline substances makes it a robust choice for diverse and challenging processing circuits.

While the initial purchase price of polyurethane screens may be higher, their total cost of ownership is typically lower. Factors contributing to this include extended service life, reduced maintenance labor, less frequent machine wear, and improved screening efficiency leading to higher throughput. For operations focused on long-term profitability and reliability, polyurethane screening media represents a sound and strategic investment.

Polyurethane screens are redefining performance standards in mineral processing and aggregate screening. By offering a combination of extended durability, operational efficiency, safety benefits, and environmental resilience, they provide a compelling upgrade over traditional screening materials. For operations aiming to optimize their screening stage, polyurethane media is not merely an alternative but a forward-looking solution engineered for modern industrial demands.

Contact Us for Expert Screening Solutions

Huatao Group specializes in high-performance polyurethane screening media tailored to your operational needs. Our technical team can assist with product selection, layout optimization, and performance troubleshooting.

Contact: Annie Lu

Email: annie.lu@huataogroup.com

Phone/WhatsApp: +86 18032422676

Website: www.huataoscreen.com

#PolyurethaneScreens #ScreeningMedia #MineralProcessing #MiningEquipment #WearResistant #ScreeningTechnology #AggregateScreening #MiningSolutions #PlantOptimization #HuataoGroup

can not be empty

can not be empty