As mining, aggregate, and recycling operations strive for greater efficiency and cost-effectiveness, polyurethane screens have emerged as a leading solution for high-performance screening applications. Their unique material properties and design advantages address key challenges faced by traditional screening media.

Extended Service Life

Polyurethane screens demonstrate exceptional abrasion resistance, particularly in demanding wet or high-impact environments. Documented performance shows 2–6 times longer operational lifespan compared to conventional steel wire mesh, significantly reducing replacement frequency and associated downtime.

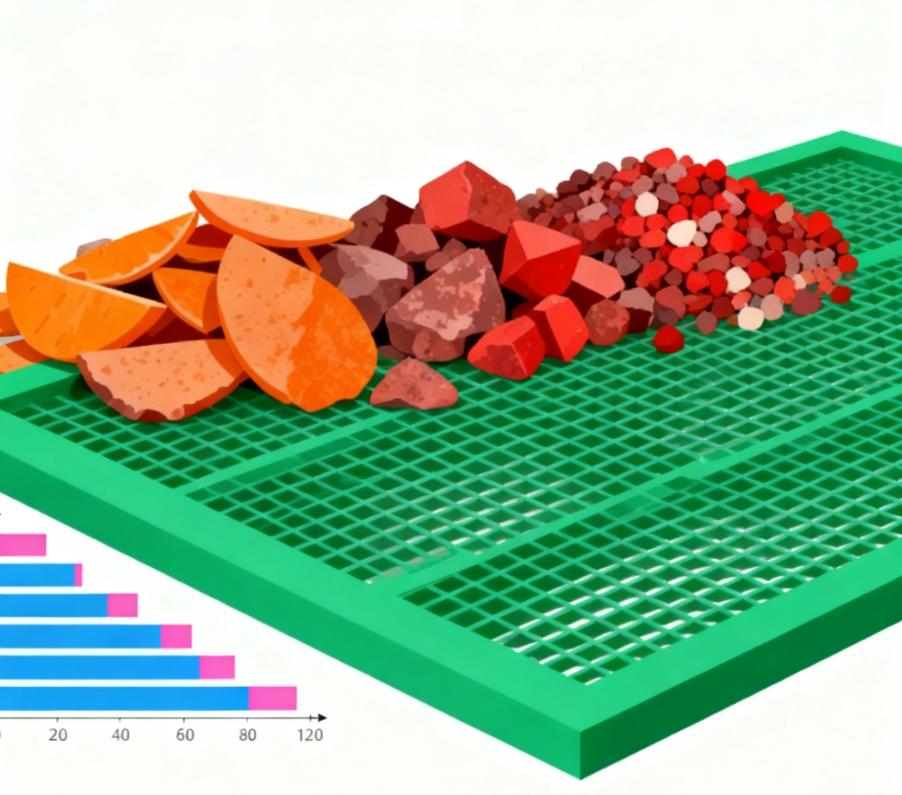

Superior Anti-Clogging Performance

The inherent elasticity of polyurethane creates dynamic surface movement during operation, preventing material adhesion and aperture blinding. Tapered aperture designs further enhance material flow, maintaining consistent screening efficiency throughout production cycles.

Enhanced Screening Precision

Advanced molding techniques ensure precise aperture dimensions and consistent panel geometry. This manufacturing precision translates to improved particle separation accuracy, especially critical in fine screening applications where size control directly impacts product quality.

Reduced Operational Impact

Polyurethane's natural vibration dampening characteristics lower noise levels and minimize structural stress on screening equipment. The lighter weight of PU panels also simplifies handling and installation, reducing maintenance time and labor requirements.

Polyurethane screening technology has gained significant traction across multiple sectors:

Mineral processing operations handling abrasive ores

Coal preparation and washing facilities

Aggregate and sand production plants

Recycling and waste processing operations

Chemical and industrial material screening

The versatility of polyurethane screens makes them suitable for diverse material types and processing conditions, from wet sticky feeds to dry abrasive applications.

Several factors contribute to the growing preference for polyurethane screening solutions:

Increasing focus on reducing cost per ton through extended component life

Growing requirements for efficient dewatering and environmental compliance

Adoption of modular screening systems for operational flexibility

Continuous improvement in polyurethane formulations enhancing durability

While polyurethane screens offer substantial benefits, optimal performance requires proper selection and installation. Key factors include:

Appropriate hardness selection based on application requirements

Correct aperture design matching material characteristics

Proper deck preparation and tensioning procedures

Lifecycle cost analysis versus initial investment

Polyurethane screens represent a significant advancement in screening technology, delivering measurable improvements in efficiency, durability, and operational cost management. As industry demands evolve, these screens continue to set new performance standards across processing applications.

For technical consultation and customized screening solutions, contact HUATAO Group.

Contact Information:

Email: annie.lu@huataogroup.com

Website: www.tufflexscreen.com

WhatsApp: +86 18032422676

#PolyurethaneScreens #MiningEquipment #ScreeningTechnology #MineralProcessing #HighPerformanceScreening #HUATAOGroup #IndustrialScreening #Efficiency #CostReduction #ScreeningSolutions

can not be empty

can not be empty