The Replacement WS 85 Modular Screen from HUATAO stands out with its open-cast polyurethane manufacturing process, where high-temperature curing strengthens molecular bonds, creating a robust structure. This engineering ensures superior durability, far outperforming traditional rubber and metal screens—ideal for tough environments like coal mines and iron ore operations.

Its acid and alkali resistance makes it versatile across corrosive conditions, from tailings dehydration to slime processing. The screen’s precise seam sizes (0.075mm to 0.8mm) enable accurate grading of diverse particle sizes, while its low friction coefficient prevents material sticking, minimizing clogging. With elastic properties, it handles large volumes efficiently, ensuring thorough dewatering.

Installation is a breeze too, with options like nails, bolts, or rail seats, and custom sizes (305×305mm, 600×600mm, etc.) fit any screen machine. The unique double-hardness MDI design—softer on top, harder beneath—boosts resilience, reducing blockages and extending service life, making it a top choice for high-performance screening.

The Replacement WS 85 Modular Screen from HUATAO stands out with its open-cast polyurethane manufacturing process, where high-temperature curing strengthens molecular bonds, creating a robust structure. This engineering ensures superior durability, far outperforming traditional rubber and metal screens—ideal for tough environments like coal mines and iron ore operations.

Its acid and alkali resistance makes it versatile across corrosive conditions, from tailings dehydration to slime processing. The screen’s precise seam sizes (0.075mm to 0.8mm) enable accurate grading of diverse particle sizes, while its low friction coefficient prevents material sticking, minimizing clogging. With elastic properties, it handles large volumes efficiently, ensuring thorough dewatering.

Installation is a breeze too, with options like nails, bolts, or rail seats, and custom sizes (305×305mm, 600×600mm, etc.) fit any screen machine. The unique double-hardness MDI design—softer on top, harder beneath—boosts resilience, reducing blockages and extending service life, making it a top choice for high-performance screening.

Key Features & Benefits of WS 85 Polyurethane Modular Screen :

| ✅ Durability: | 8–10x lifespan vs. steel, anti-abrasion, tear-resistant. |

| ✅ Efficiency: | Self-cleaning, anti-clogging, 30% energy saving. |

| ✅ Customization: | Aperture sizes (0.1–170mm), shapes, modular compatibility. |

| ✅ Certified: | Flame-retardant, non-toxic, ISO-compliant. |

Specification of WS85 PU Screen Panel:

| Material | steel frame and polyurethane surface |

| Feature | WS85,Wear-resistant, efficient and easy to install |

| Thickness | 30mm, 40mm, 50mm |

| Opening size | Slot Width 0.1mm – 2.5mm |

| Screen Width | 305mm, 500mm and 515mm, others can be designed. |

| Screen length | 305mm, 610mm, 650mm, 915mm, 1200mm and 1220mm, others can be designed. |

| Connection type | WS85 |

| Application | * Mining: Ideal for grading iron ore, copper, limestone, and granite. * Coal Processing: Efficient dewatering and desliming in coal preparation plants. * Aggregates & Quarries: High-precision screening of sand, gravel, and crushed stone. * Recycling & Waste Management: Separation of construction debris and industrial waste. |

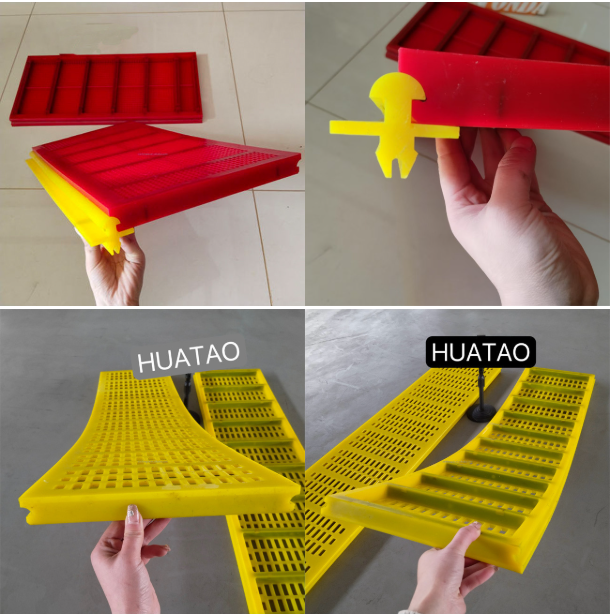

Images of Polyurethane Dewatering Screen Panel include:

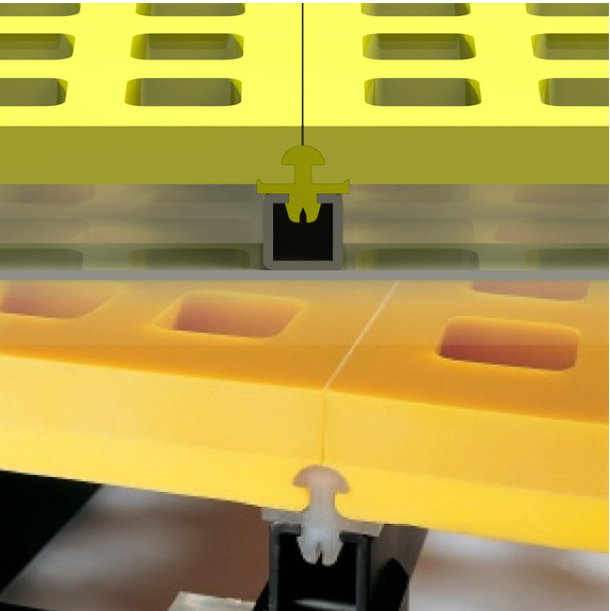

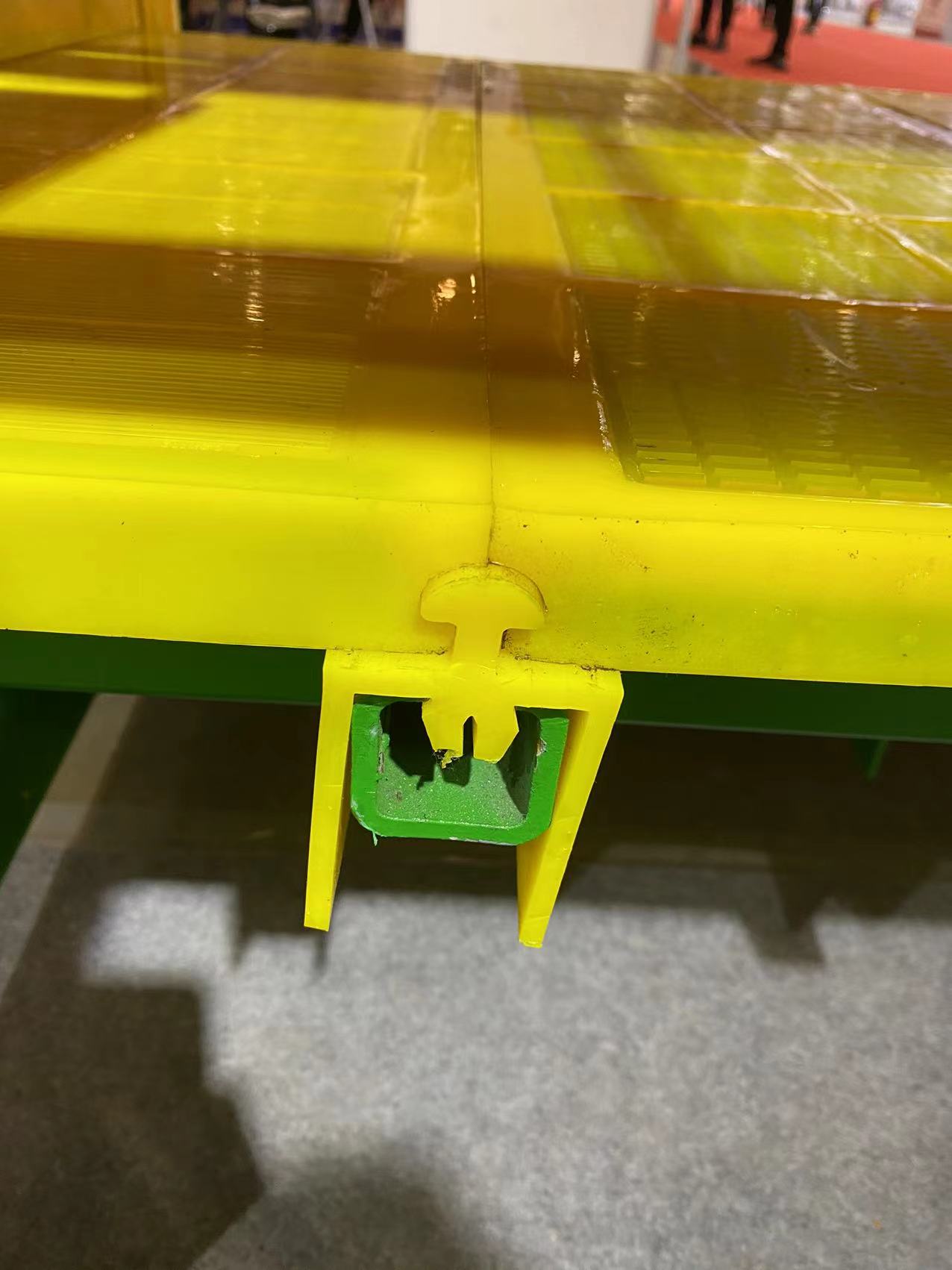

A close-up of the Polyurethane Dewatering Screen Panel Pin&Legs showing :

Working Processing of WS85 Polyurethane Dewatering Screen Panel:

Packaging & Logistics: Wooden box package.

Application of Polyurethane Dewatering Screen Panel

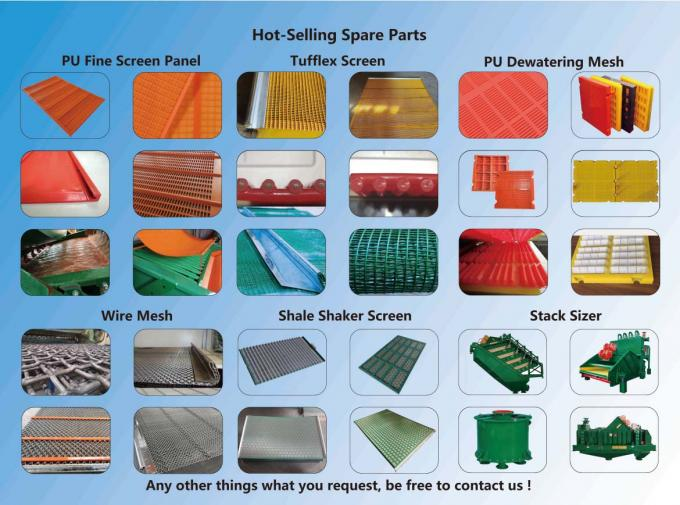

HUATAO Hot-Selling Polyurethane Product List as below:

| Polyweb Urethane Screen | Tufflex Screen |

| Polyurethane Dewatering Screen Mesh | WS 85 Modular Screen |

| Polyurethane Screen Panels | Rotex Replacement Screens |

| Rubber Screen Panel | Vibrating Screen Mesh |

| Self cleaning Wire Mesh | Shale Shaker Screen |

can not be empty

The E-mail format is not correct

can not be empty