The banana screen adopts the principle of equal thickness screening proposed by Boerstrein, France, and the screen surface is arranged in five or six sections with different inclination angles. Its unique structure makes it more suitable for working conditions with a large number of fine particles in the material, and the classification effect of medium and fine coal is more significant. In the coal industry, banana screen is a new application, which can replace multiple equal thickness screening systems consisting of a series of circular vibrating screens or linear screens.

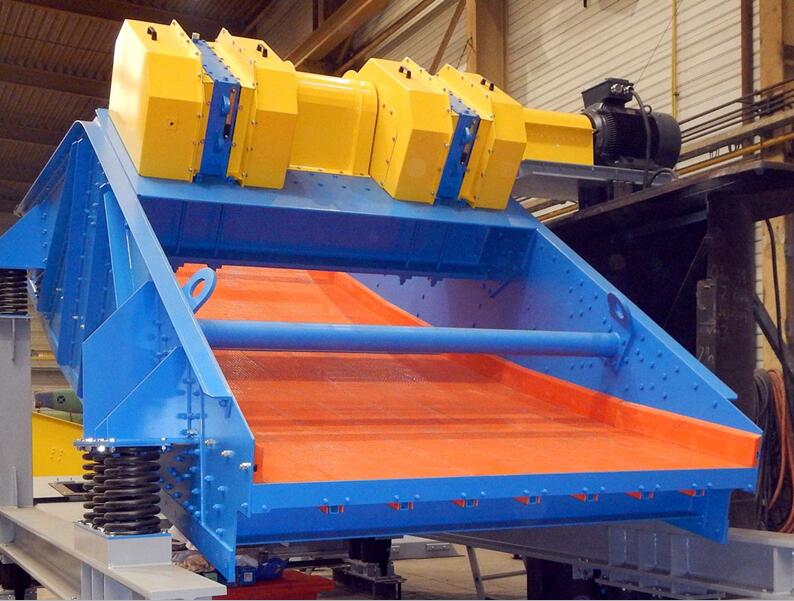

Description of Banana Screen

The banana screen adopts the principle of equal thickness screening proposed by Boerstrein, France, and the screen surface is arranged in five or six sections with different inclination angles. Its unique structure makes it more suitable for working conditions with a large number of fine particles in the material, and the classification effect of medium and fine coal is more significant. In the coal industry, banana screen is a new application, which can replace multiple equal thickness screening systems consisting of a series of circular vibrating screens or linear screens.

Instructions of banana screen :

1.Banana sieve is suitable for high-load screening, dehydration and de-intermediation operations with feed particle size ≤300mm and classification particle size of 0.5-100mm;

2.The screen panels can be used metal woven screen wire mesh, stainless steel slit wire mesh, polyurethane screen or polyurethane rail seat screen(WS85);

3.Giant square beam, rubber-coated protection, 610mm long feeding buffer protection, large layer spacing design is convenient for maintenance;

4.Using NJ exciter, standard FAG or SKF bearing;

5.Self-synchronization technology, gear-free maintenance, low noise and high working reliability;

6.When ordering, in addition to indicating the model and quantity, the user must also indicate the size of the sieve hole, the form of the sieve mesh and the installation angle of the sieve machine;

7.The motor can be installed on the left or right side, please specify if there are installation requirements, otherwise it will be supplied in the form of left-side installation;

8.Optional automatic lubrication device.

can not be empty

The E-mail format is not correct

can not be empty