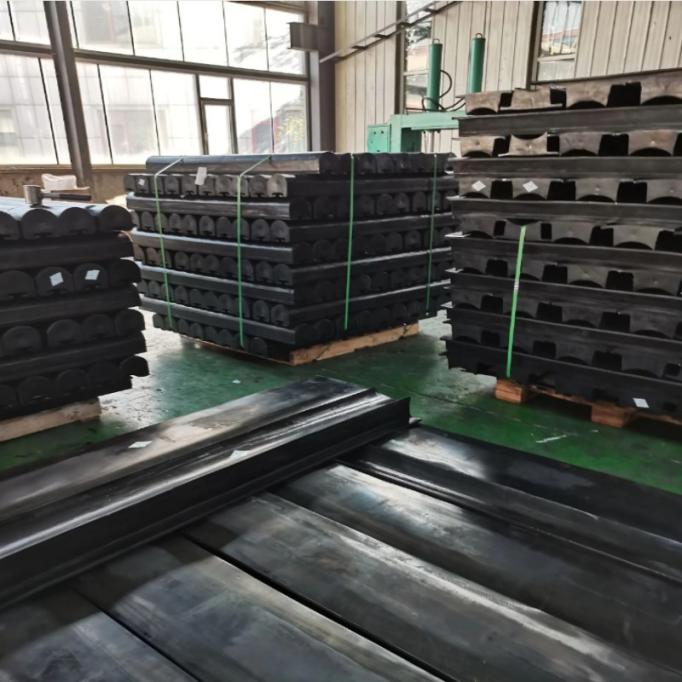

In mineral processing operations, internal equipment wear significantly impacts production stability and maintenance costs. Mining rubber liners are increasingly adopted as an effective solution to protect mills and material handling systems operating under abrasive and high-impact conditions.

Designed from advanced rubber compounds, these liners combine flexibility with high wear resistance. Unlike rigid metal liners, rubber absorbs impact energy and minimizes stress concentration, reducing the likelihood of structural damage and fatigue cracking.

The installation of rubber liners contributes to lower noise levels and vibration during mill operation, improving workplace safety. Their corrosion resistance also makes them well suited for wet grinding environments where slurry exposure is constant.

Mining rubber liners are applied in ball mills, SAG mills, rod mills, transfer chutes, hoppers, and slurry systems. Custom design options enable operators to match liner hardness, thickness, and configuration to specific ore characteristics and throughput requirements.

As mining operations pursue efficiency, safety, and cost control, rubber liner technology continues to demonstrate measurable improvements in wear life and maintenance performance.

Annie Lu

Huatao Group

Email: annie.lu@huataogroup.com

Mobile: +86 18032422676

Website: www.tufflexscreen.com

#MiningRubberLiners #MillLiners #WearProtection #MiningEquipment #MineralProcessing

#RubberMillLiners #BallMill #SAGMill #WearResistant #SlurrySystems

#OreProcessing #MiningIndustry #PlantEfficiency #IndustrialLiners #ImpactResistance

#CorrosionResistance #ProcessOptimization #MiningTechnology #HuataoGroup #SustainableMining

can not be empty

can not be empty