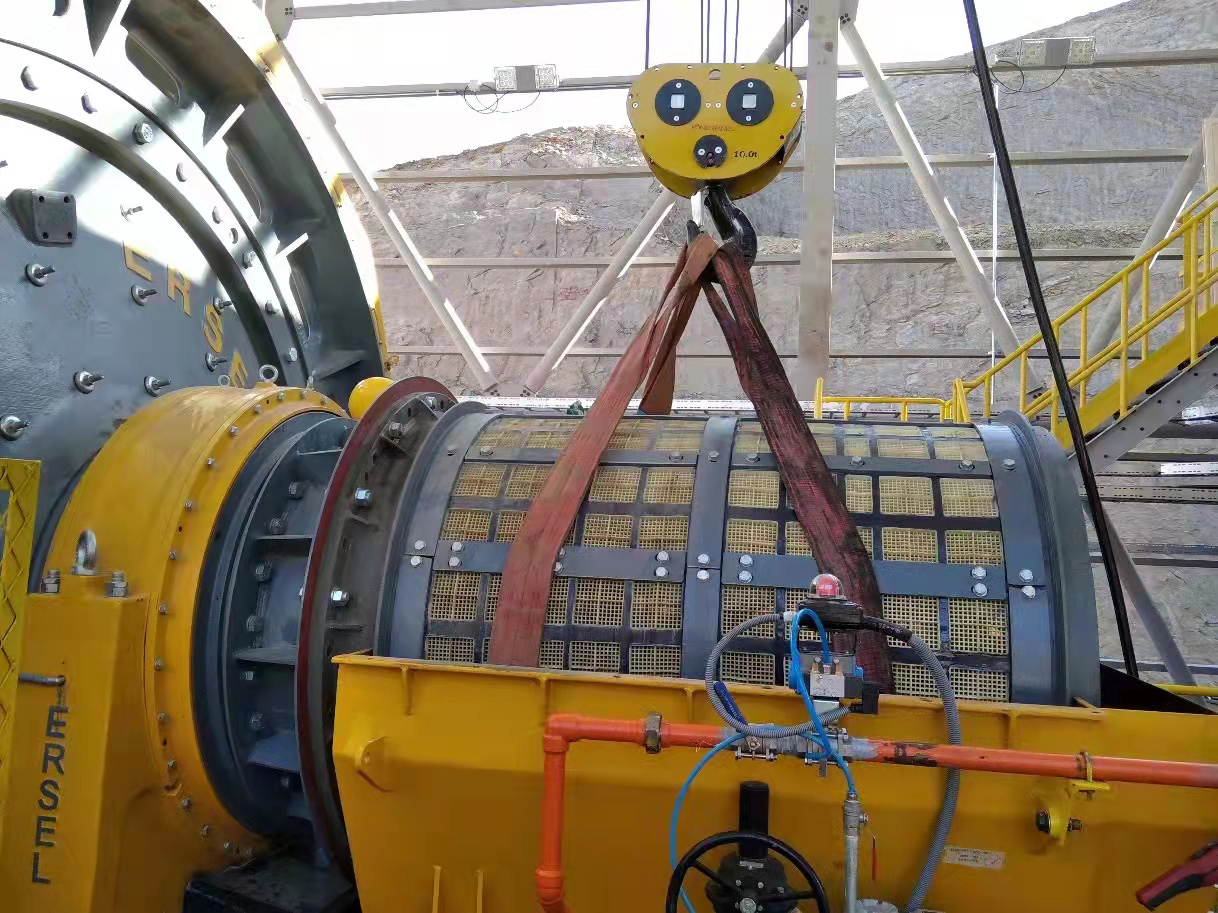

Trommel screen panels are specialized, replaceable screening surfaces that form the cylindrical drum of a trommel screen. As the trommel rotates, these panels efficiently separate materials by size through a tumbling action. Available in various materials including rubber, polyurethane, and woven wire, they feature different aperture sizes and configurations to meet specific operational needs across multiple industries.

Trommel screen panels are specialized, replaceable screening surfaces that form the cylindrical drum of a trommel screen. As the trommel rotates, these panels efficiently separate materials by size through a tumbling action. Available in various materials including rubber, polyurethane, and woven wire, they feature different aperture sizes and configurations to meet specific operational needs across multiple industries.

Size-Based Sorting: As the trommel rotates, material enters at one end, with smaller particles falling through the screen apertures due to gravity while larger particles travel to the discharge end.

Durable Materials: Manufactured from wear-resistant rubber, long-lasting polyurethane (PU), or robust woven wire mesh

Heavy-Duty Performance: Engineered to withstand abrasive materials and demanding operating conditions

Aperture Variety: Available in square, round, or slotted openings

Configuration Flexibility: Designed to meet specific process requirements and material characteristics

Secure Attachment: Compatible with bolt-on or pin-and-sleeve fastening systems for reliable connection to the trommel frame

Modular Configuration: By combining different panel types, a single trommel screen can be adapted to produce multiple material size fractions

| Industry Sector | Primary Uses |

|---|---|

| Mining & Mineral Processing | Separating aggregates and heavy materials in milling circuits |

| Recycling Operations | Sorting C&D materials, waste streams, and auto shredder residue |

| Organics Processing | Screening compost, mulch, and other biodegradable materials |

Trommel screen panels serve as critical components in material separation systems, offering durability, customization, and operational flexibility. Whether in mining, recycling, or organic processing applications, their robust construction and adaptable design ensure efficient size-based sorting while withstanding the challenges of heavy-duty operations.

can not be empty

The E-mail format is not correct

can not be empty