Mining screening media are the replaceable, perforated surfaces installed on vibrating screens, designed to separate raw materials by size.

They are critical components in processing plants, directly influencing screening efficiency, accuracy, and overall production throughput.

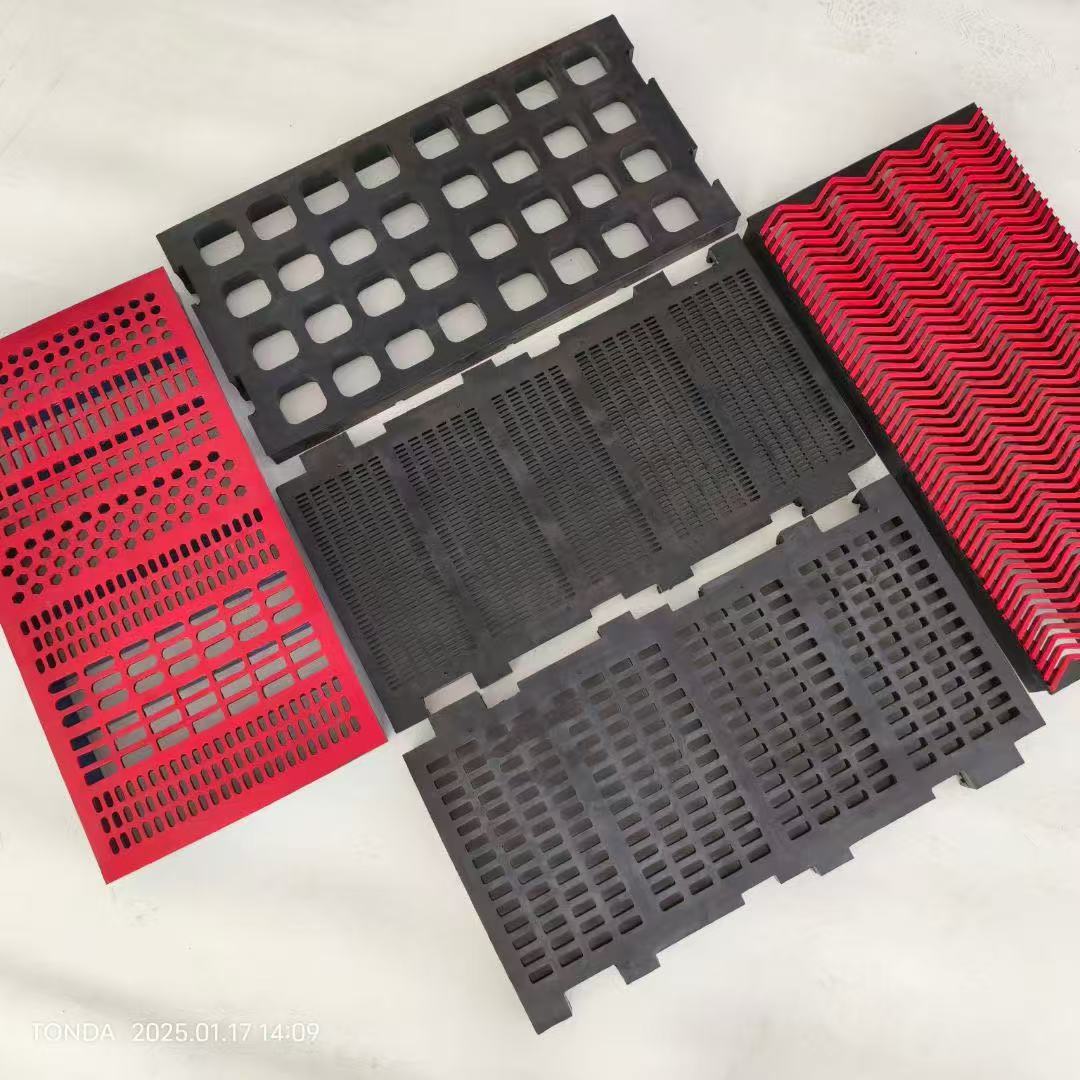

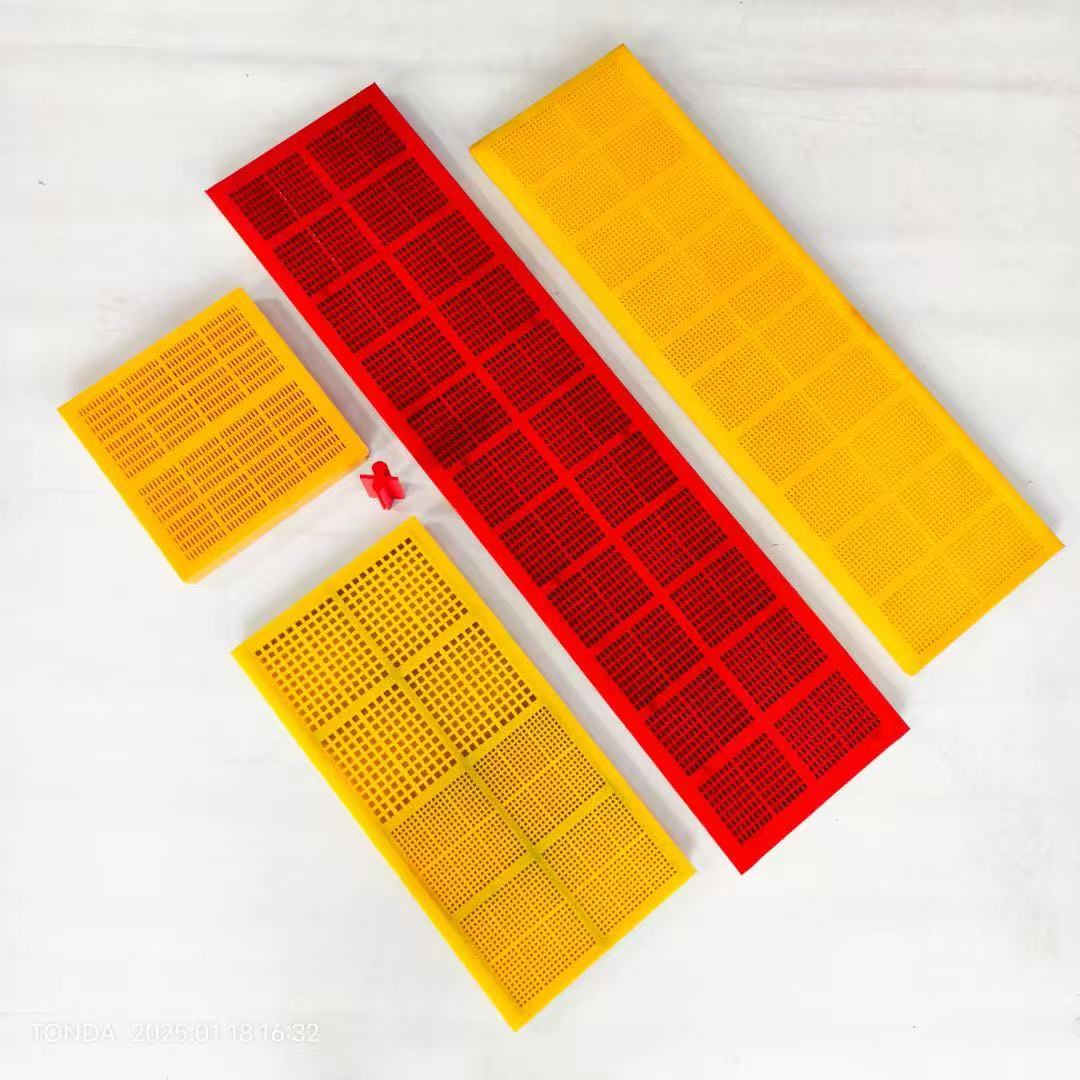

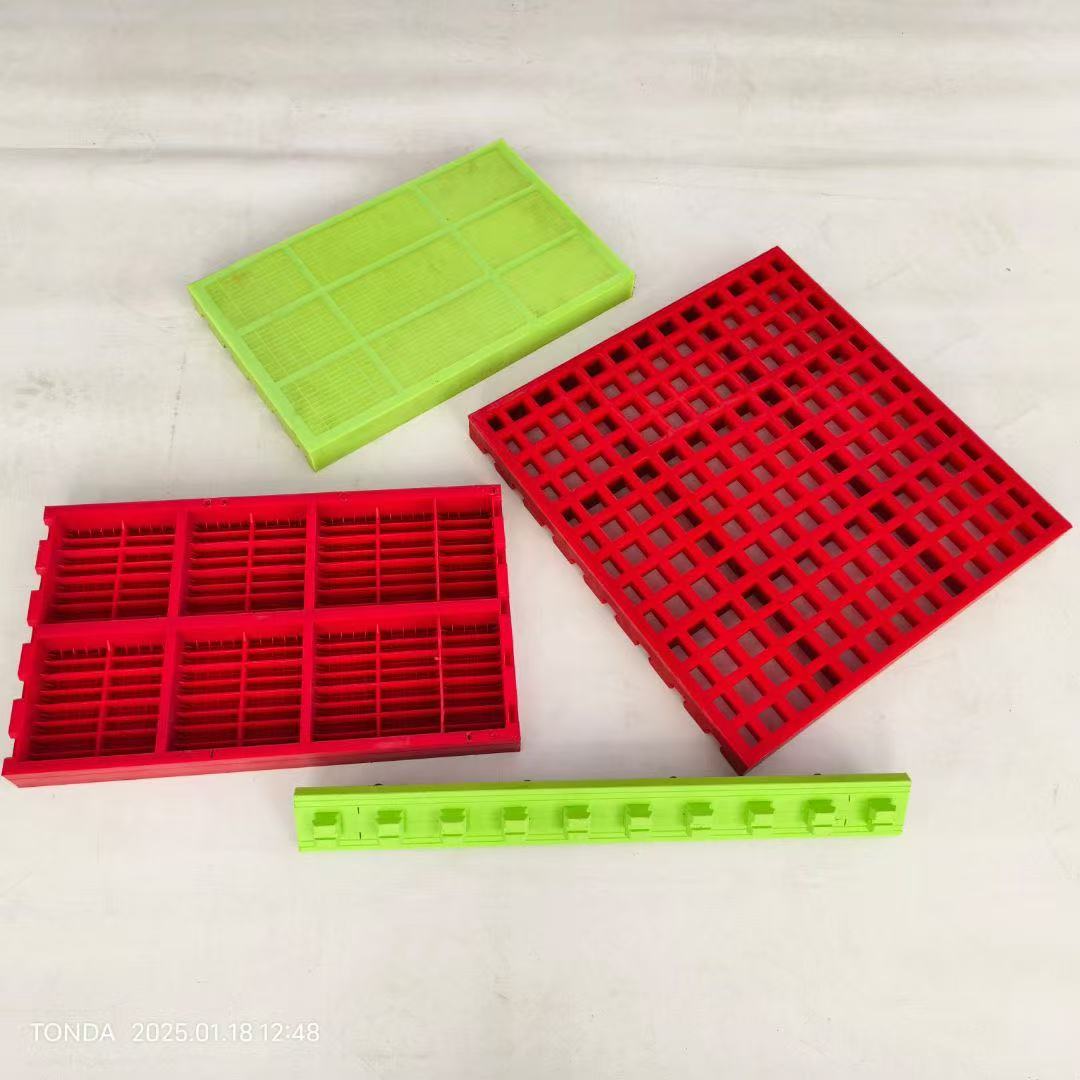

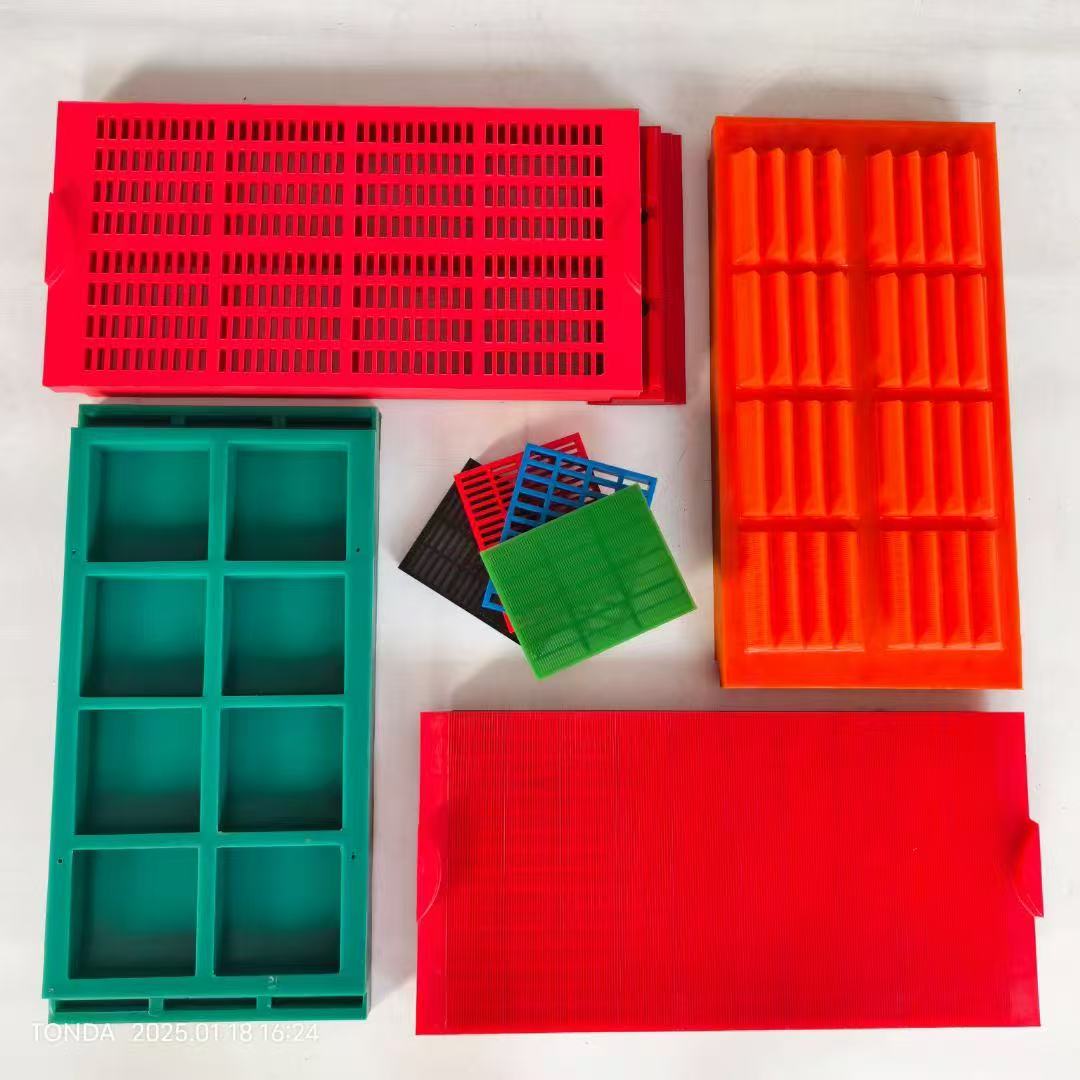

These media are manufactured from a variety of materials—including steel wire, rubber, and polyurethane—each selected based on the material being processed and specific operating conditions.

What Are Mining Screening Media?

Mining screening media are the replaceable, perforated surfaces installed on vibrating screens, designed to separate raw materials by size.

They are critical components in processing plants, directly influencing screening efficiency, accuracy, and overall production throughput.

These media are manufactured from a variety of materials—including steel wire, rubber, and polyurethane—each selected based on the material being processed and specific operating conditions.

Separation Process:

As raw material is fed onto the vibrating screen, particles smaller than the screen’s openings (apertures) pass through, while larger particles are retained on the surface.

Oversize & Undersize:

The material that passes through is referred to as “undersize,” while the material remaining on top is the “oversize.”

Stratification Effect:

The vibration causes finer particles to settle downward and pass through the apertures, while coarser particles rise to the top—a key mechanism known as stratification.

| Type | Material & Features | Common Applications |

|---|---|---|

| Woven Wire Mesh | High-tensile steel; durable and reliable | Sand, gravel, aggregates |

| Rubber & Polyurethane | Excellent impact resistance, flexibility; polyurethane offers extended wear life | Abrasive or heavy materials |

| Installation Method | WS85 Type,Hook Type,Bolt Type | |

| Match Brand | Mesto, Trelleborg, Sandvik, Schenck,Multotec,Aury,Landsky Eurocma | |

| Wedge Wire Screens | Unique profile design; enhances screening efficiency and resists clogging | Fine and difficult-to-screen materials |

Product Quality Control

Ensures final products meet precise size and quality specs for downstream processing or direct sale.

Enhanced Process Efficiency

Reduces issues like “blinding” (clogging) and “pegging,” which helps maximize throughput and minimize unplanned downtime.

Equipment Protection

Removes oversized or foreign materials early in the process, safeguarding downstream machinery from damage and wear.

Choosing the right screening media is essential for optimizing mineral processing performance. Whether you're screening sand, gravel, or highly abrasive ores, selecting the appropriate type—wire, rubber, or polyurethane—can significantly impact productivity, cost, and operational reliability.

Let me know if you'd like help selecting the best screening media for your application!

can not be empty

The E-mail format is not correct

can not be empty