Across mining, aggregate production, and numerous process industries, vibrating screens perform the essential task of particle size separation. While screen motion and feed rate are often the focus of operational tuning, the screen mesh itself serves as the decisive interface where separation actually occurs. Its design, material, and condition directly govern screening accuracy, capacity, product purity, and long-term operating costs.

This article examines the key parameters of screen mesh and provides a structured framework for selecting and maintaining meshes to achieve sustained screening performance.

Aperture Dimensions: The Foundation of Separation

Aperture size determines the theoretical cut-point—the particle size at which separation occurs. Larger apertures support higher throughput but may compromise product cleanliness, while smaller apertures improve precision at the expense of capacity and increased blinding susceptibility.

Aperture geometry further tailors performance:

Square openings are versatile for general classification.

Slotted apertures enhance dewatering and separation of flaky or fibrous materials.

Round holes can maximize open area for specific high-flow applications.

Open Area: Balancing Capacity and Durability

The percentage of open space in the screen surface significantly influences material passage rate. High open area promotes greater throughput and screening efficiency but often requires careful engineering to maintain structural integrity, especially in fine-aperture screens. Perforated polyurethane or rubber panels frequently provide higher open area than woven metal meshes of equivalent aperture size.

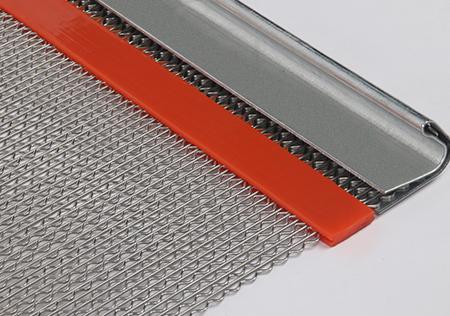

Wire Diameter and Tension: Ensuring Operational Stability

In woven screens, wire diameter involves a direct trade-off: thicker wires improve wear resistance but reduce open area; thinner wires increase open area but may sacrifice longevity. Selecting the appropriate diameter depends on material abrasiveness and desired service life.

Screen tension is a critical, often overlooked, parameter. Adequate tension ensures uniform vibration transmission across the entire mesh, enabling consistent material stratification and efficient sizing. Inadequate tension results in localized “pounding,” uneven screening, uncontrolled particle movement, and premature mesh failure.

Material Selection: Matching Mesh to Operating Environment

Stainless Steel: Offers a balance of corrosion resistance, strength, and cost efficiency.

High-Carbon Steel: Preferred for highly abrasive materials like iron ore or granite.

Polyurethane/Rubber: Provide exceptional wear resistance, noise reduction, and anti-blinding characteristics, with designs that include tapered apertures to resist clogging.

Ceramics/Special Alloys: Employed in extreme wear or corrosive conditions.

Mesh construction—whether woven, welded, perforated, or modular—also influences performance, with each type offering distinct advantages in rigidity, open area, and application suitability.

Blinding (Clogging): Caused by moisture, static charge, or near-size particles. Solutions include screens with tapered or self-cleaning apertures, ultrasonic vibration systems, or surface treatments that reduce adhesion.

Abrasive Wear: Leads to gradual aperture enlargement, shifting the effective cut-point and contaminating product streams. Selecting wear-resistant materials or applying protective surface treatments are effective countermeasures.

Effective screening requires harmony between mesh characteristics and screen motion. Linear, circular, or elliptical vibration patterns each promote different material behavior; the mesh must complement these motions to facilitate stratification, conveyance, or fine separation. Heavy-duty applications demand robust, high-tension screens, while precision screening benefits from finely tensioned, high-open-area designs.

Optimizing screening performance requires shifting from a consumable-based to a component-based view of screen mesh. A systematic workflow includes:

Analyzing material properties (size distribution, moisture, shape, abrasiveness).

Defining process requirements (target accuracy, throughput).

Selecting mesh parameters (aperture, material, construction) accordingly.

Ensuring professional installation and correct tensioning.

Implementing regular inspections and preventive maintenance schedules.

By treating screen mesh as a strategic investment, operations can achieve significant gains in efficiency, product quality, and cost control.

For expert guidance on screen mesh selection or to discuss your specific screening challenges, contact our technical team:

Annie Lu | Huatao Group

Email: annie.lu@huataogroup.com

Mobile/WhatsApp: 0086 18032422676

Website: www.tufflexscreen.com

#ScreenMesh #VibratingScreenEfficiency #MeshSelection #ScreeningTechnology #IndustrialScreening #ApertureDesign #OpenArea #ScreenTension #WearResistance #BlindingPrevention #ProcessOptimization #MiningEquipment #AggregateScreening #MaterialSeparation #ProductQuality #OperationalCosts #PreventiveMaintenance #HuataoGroup #ScreeningSolutions #PerformanceOptimization

can not be empty

can not be empty