Jaw crushers remain fundamental equipment in primary crushing circuits across mining and construction industries. While often regarded as routine consumables, jaw plates play a decisive role in crushing efficiency, wear rate, and production stability.

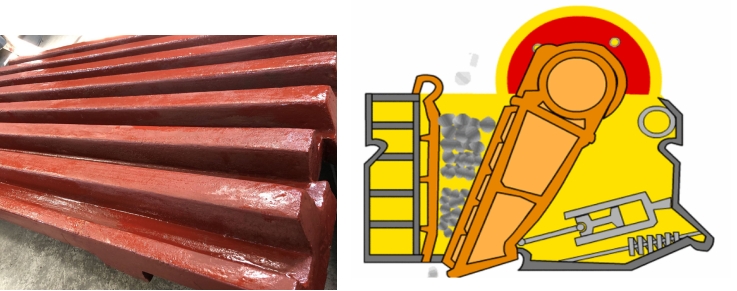

The structural function of jaw plates is to form the crushing chamber, where material is subjected to repeated compression and bending. The performance of these components depends on material composition, tooth profile geometry, and compatibility with the crusher model.

Modern high-manganese alloys demonstrate strong work-hardening behavior, increasing surface hardness under impact. Composite and modified alloys further enhance wear resistance while maintaining toughness, reducing the risk of premature failure. Tooth profile design also contributes significantly to crushing performance by influencing material capture and compression dynamics.

Selecting jaw plates based on material characteristics, production requirements, and equipment specifications helps minimize downtime and reduce operating costs. Proper installation and maintenance practices further ensure long-term performance.

As mining operations seek greater efficiency and cost control, strategic jaw plate selection is becoming a key factor in optimized crushing systems.

Annie Lu

Huatao Group

Email: annie.lu@huataogroup.com

Mobile: +86 18032422676

Website: www.tufflexscreen.com

#JawCrusher #JawPlate #CrusherPerformance #MiningEquipment #WearParts

#CrusherMaintenance #MiningEfficiency #ManganeseSteel #CrushingTechnology #OreProcessing

#QuarryEquipment #MechanicalWear #ProcessOptimization #PlantEfficiency #CrusherParts

#EngineeringMaterials #MiningIndustry #CostReduction #HuataoGroup #MineralProcessing

can not be empty

can not be empty