As mining operations adapt to lower ore grades and higher efficiency demands, optimizing the crushing circuit has become increasingly important. Crusher selection is no longer a simple capacity decision—it directly affects energy use, product consistency, and downstream processing performance.

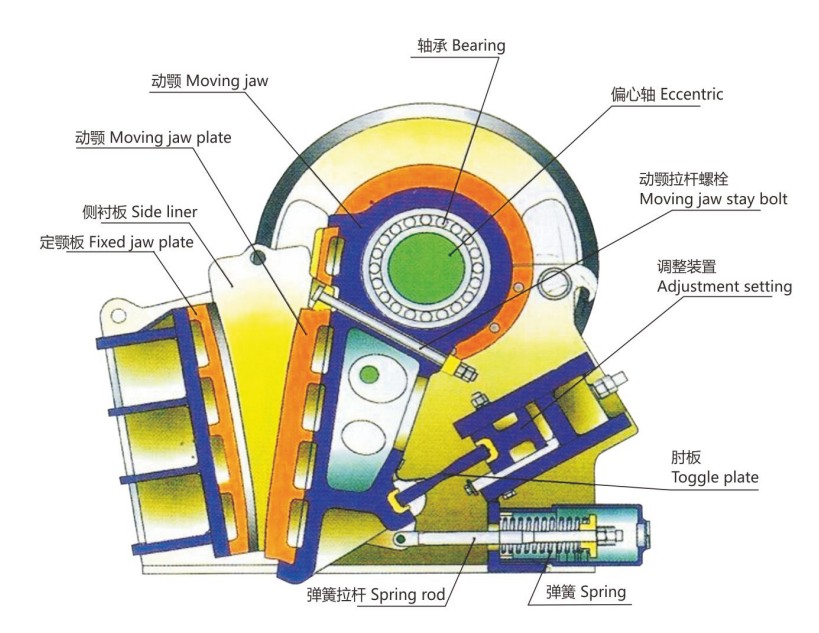

Jaw, cone, and impact crushers each operate using different particle reduction mechanisms. Compression-based crushers, such as jaw and cone models, apply steady pressure to break hard, abrasive materials with high energy efficiency. Impact crushers rely on high-velocity collisions, making them suitable for medium-hard materials and applications where particle shape is critical.

The role of each crusher type varies across the crushing stages. Jaw crushers typically perform primary size reduction for large feed materials. Cone crushers refine material in secondary and tertiary stages, providing controlled product size and durability in abrasive conditions. Impact crushers are often used when superior particle shape or higher reduction ratios are required.

Selecting the appropriate crusher combination allows operations to balance wear costs, energy efficiency, and product quality. By aligning equipment choice with material properties and production targets, mining plants can improve throughput while reducing operating costs and environmental impact.

Strategic crusher selection is becoming a central element of modern mineral processing design, enabling more sustainable and economically efficient operations.

Annie Lu

Huatao Group

Email: annie.lu@huataogroup.com

Mobile: +86 18032422676

Website: www.tufflexscreen.com

#CrusherSelection #MiningTechnology #CrushingCircuit #JawCrusher #ConeCrusher

#ImpactCrusher #MineralProcessing #MiningEquipment #Comminution #ProcessOptimization

#AggregateProduction #OreProcessing #MiningInnovation #EnergyEfficiency #IndustrialCrushing

#MiningOperations #ScreeningAndCrushing #PlantDesign #HuataoGroup #MiningIndustry

can not be empty

can not be empty