Screen mesh clogging, commonly known as blinding, is a frequent yet disruptive issue in vibrating screen operations across mining, quarrying, and industrial processing plants. It not only reduces effective screening area but also leads to diminished throughput, increased energy consumption, and unscheduled maintenance stops.

This article provides a detailed examination of the factors that contribute to screen clogging and outlines a set of practical, implementable solutions designed to restore and maintain optimal screening function.

Clogging fundamentally reduces the open area through which material can pass. It is typically driven by:

Particle Wedging: Near-size particles become mechanically trapped in apertures.

Surface Adhesion: Moist, sticky, or electrostatically charged materials build up on screen surfaces.

Understanding the origin of clogging is the first step toward a solution. Causes are generally divided into two categories:

Material-Dependent Factors:

Elevated Moisture Levels: Materials with high water content (>5%) agglomerate, increasing adhesion to screen surfaces.

Inherent Adhesiveness or Electrostatic Charge: Certain ores, clays, or processed powders exhibit cohesive or static properties that promote buildup.

Particle Shape and Density: Flaky, fibrous, or very lightweight particles are more likely to block openings.

Unfavorable Size Distribution: A high concentration of particles close to the screen aperture size raises the risk of blinding.

Screen and Equipment Factors:

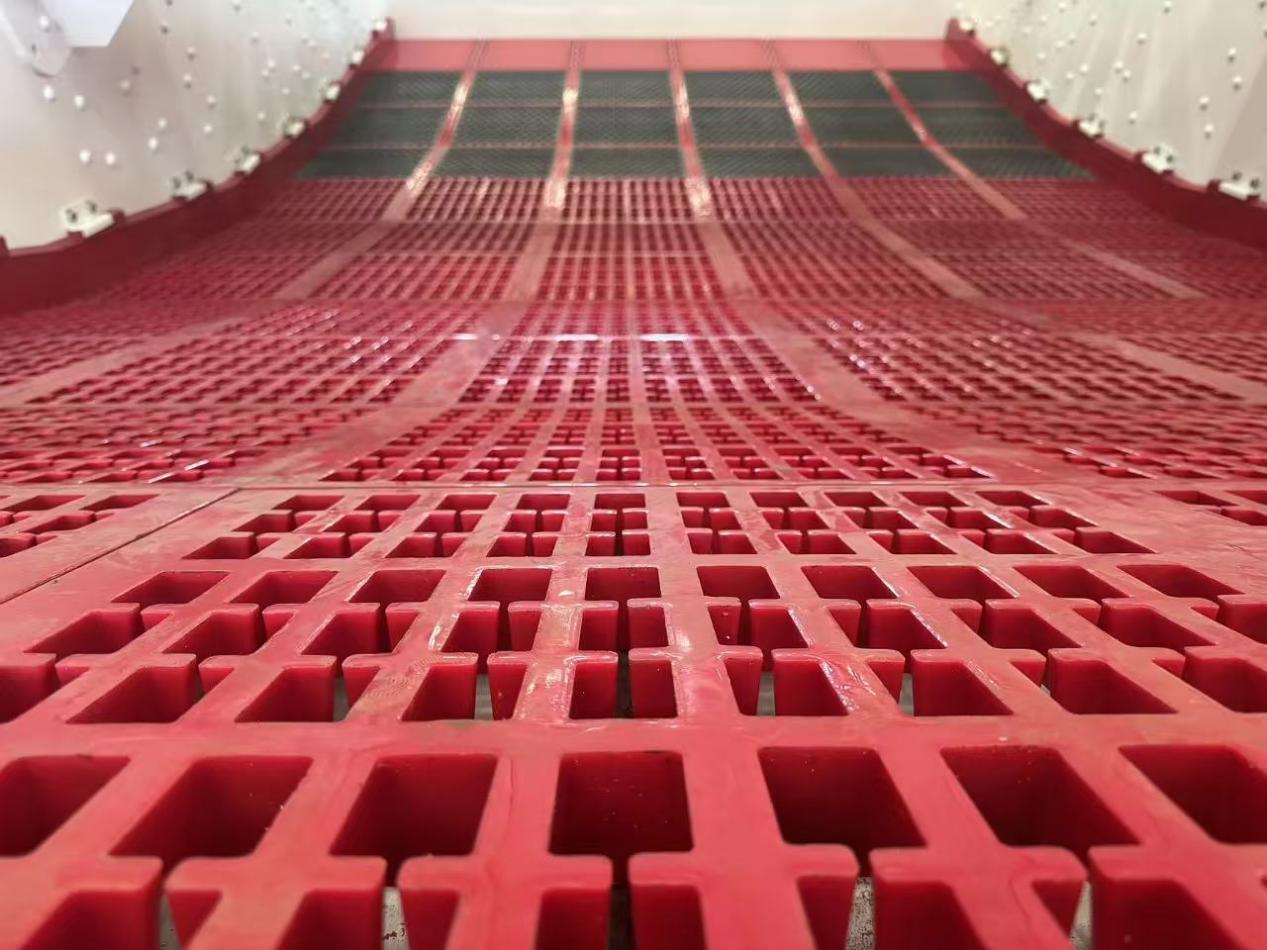

5. Suboptimal Screen Design: Using screens with incorrect aperture geometry, inadequate open area, or unsuitable surface characteristics for the material.

6. Insufficient On-Board Cleaning: Lack of integrated cleaning devices limits self-cleaning capability during operation.

Implementing the following strategies can significantly reduce blinding and enhance screening continuity:

Strategic Screen Media Selection and Feed Conditioning

Choose screens with aperture shapes (e.g., slotted, square, anti-blinding) and dimensions matched to material characteristics.

Where moisture is an issue, employ pre-drying, wet screening, or surface-treated screens. For static-prone materials, anti-static screens or ionization systems can be effective.

Integration of Automatic Cleaning Systems

Install rubber bouncing ball decks beneath screen panels to generate impact-based cleaning.

For persistent or fine-material blinding, consider ultrasonic cleaning systems that use high-frequency vibrations to dislodge particles.

Precision Adjustment of Operational Parameters

Maintain appropriate screen tension to induce secondary vibrations that help clear apertures.

Calibrate vibration amplitude and frequency to optimize material travel and stratification without promoting re-blinding.

Upstream Process Modifications

Adjust crushing and grinding stages to yield a more favorable particle size distribution, reducing the proportion of near-mesh material.

Implement multi-deck or multi-stage screening layouts to distribute the screening load more evenly.

Consistent Maintenance and Monitoring

Establish routine inspection schedules to detect early signs of wear or blockage.

Perform thorough cleaning during planned downtime and document performance trends to guide future screen selection and process tuning.

Persistent screen clogging is rarely solved by a single adjustment. A holistic approach—combining the right screen technology, tailored cleaning aids, process optimization, and disciplined maintenance—delivers lasting improvements in screening efficiency and equipment longevity.

For professional support in screen media selection or clogging troubleshooting, our engineering team is ready to assist:

Annie Lu | Huatao Group

Email: annie.lu@huataogroup.com

Mobile/WhatsApp: 0086 18032422676

Website: www.tufflexscreen.com

#ScreenClogging #VibratingScreenMaintenance #BlindingSolutions #ScreeningPerformance #IndustrialScreens #ProcessOptimization #MaterialHandling #MiningEquipment #QuarryOperations #MaintenanceStrategies #ProductionUptime #ScreenMedia #AntiBlinding #UltrasonicCleaning #FeedConditioning #OperationalEfficiency #HuataoGroup #ScreeningTechnology #PreventiveMaintenance #ThroughputImprovement

can not be empty

can not be empty